I. Introduction: The Centrifuge as the Cornerstone of Quality and Profitability

The modern cannabis and botanical extraction landscape is a highly competitive, rapidly maturing industry. The era of makeshift solutions and inconsistent processes is decisively over; market leadership and long-term success now hinge on the implementation of industrial-grade, reliable, and compliant processing equipment.1 As regulatory oversight intensifies and consumer expectations for product quality and consistency rise, extraction facilities are increasingly adopting the rigorous standards of the pharmaceutical and food processing sectors.2

At the heart of this transformation lies a critical operational challenge: the efficient and pure separation of valuable cannabinoids and terpenes from raw plant biomass. The centrifuge, a machine that applies immense rotational force to separate materials of different densities, is not merely another piece of equipment in the production line. It is the cornerstone of the extraction process, a pivotal asset that directly dictates final product yield, purity, operational efficiency, and, ultimately, the profitability of the entire facility.3 An investment in the right centrifuge is an investment in the quality of the final product and the financial health of the business.

This guide provides a comprehensive, engineering-focused framework for selecting the optimal botanical centrifuge for a cannabis extraction facility. It is designed to move beyond superficial marketing claims and equip engineers, operations managers, and procurement specialists with the technical knowledge to make an informed, strategic capital investment. This analysis will navigate the core principles of centrifugal separation, establish critical selection criteria for various scales of operation, provide a robust model for evaluating economic returns, and detail model-specific applications. The objective is to empower decision-makers to choose a solution that not only meets their immediate production needs but also supports their long-term goals for growth, compliance, and market leadership.

The evolution of the cannabis industry from a craft-based market to a quasi-pharmaceutical model is the single most important trend influencing these equipment purchasing decisions. Initially, small-scale operations with limited regulatory oversight had simpler equipment needs. However, as markets legalize and consolidate, the objectives shift towards large-scale production, interstate commerce, and even international export.1 This progression naturally invites stricter regulations that mirror those found in the food and pharmaceutical industries, where product consistency, purity, and verifiable dosing are non-negotiable.2 Consequently, the criteria for equipment selection have fundamentally changed. The question is no longer simply “Does it work?” but rather, “Is it compliant with Good Manufacturing Practices (GMP)? Is it scalable? Can the process be validated? Does it produce a consistent, high-quality product every single time?” This paradigm shift creates a significant advantage for manufacturers with a proven legacy in highly regulated sectors, as the principles of robust engineering, reliability, and process control are already embedded in their design philosophy.6

II. The Science of Separation: Centrifugation in Cryogenic Ethanol Extraction

To select the right centrifuge, one must first understand the scientific principles that govern its function within the most common and efficient extraction method used today: cryogenic ethanol extraction. This process leverages the unique properties of chilled ethanol and the physics of centrifugal force to achieve a highly selective and efficient separation.

The Role of Cryogenic Temperatures

The use of extremely cold ethanol—often chilled to temperatures of -40°C (-40°F) or lower—is the critical first step in producing a high-purity extract.7 At these cryogenic temperatures, ethanol becomes a highly selective solvent. It efficiently dissolves the target non-polar compounds, namely cannabinoids (like CBD and THC) and volatile terpenes, while leaving behind undesirable water-soluble and less-soluble compounds such as waxes, lipids, and chlorophyll.10 This temperature-driven selectivity acts as a crucial pre-purification step. By preventing these undesirable components from being co-extracted with the cannabinoids, the need for extensive and costly downstream post-processing steps like winterization (also known as dewaxing) is dramatically reduced or even eliminated.11 The result is a cleaner, more valuable initial extract and a more streamlined, efficient overall workflow.

The Physics of Centrifugal Force

At its core, a centrifuge is a device that replaces the force of gravity with a much more powerful centrifugal force to accelerate the separation of materials with different densities.13 This force is generated by spinning a basket containing the material at high speeds. The effectiveness of this force is measured not just by the rotational speed in Revolutions Per Minute (RPM), but by the Relative Centrifugal Force (RCF), often expressed in multiples of gravity (Gs).14

In the context of ethanol extraction, the centrifuge is tasked with separating the low-density, cannabinoid-rich ethanol tincture (the liquid phase) from the high-density, saturated plant biomass (the solid phase). By applying thousands of Gs of force, the centrifuge rapidly forces the liquid tincture through a fine mesh filter screen or bag lining the basket, while the solid biomass is pinned against the basket wall, compacting it into a dense cake.15 This high-force separation is far more efficient and complete than simple gravity draining or mechanical pressing, allowing for maximum recovery of the valuable tincture.

A Typical Centrifuge Extraction Cycle

While specific parameters can be adjusted, a standard batch cycle in a botanical centrifuge follows a distinct, automated sequence:

- Loading: The centrifuge basket, lined with an appropriate micron-rated filter bag, is loaded with pre-chilled, cryo-ground cannabis or hemp biomass.

- Flooding: The sealed centrifuge is flooded with a precise volume of cryogenic ethanol, fully immersing the biomass.

- Agitation: The basket undergoes a slow, bi-directional (alternating clockwise and counter-clockwise) rotation. This gentle agitation ensures that the cold ethanol thoroughly permeates the biomass, dissolving the target cannabinoids and terpenes without mechanically degrading the plant material, which could release more impurities.16

- Spin Dry: Following the agitation phase, the centrifuge controller ramps the motor up to a high rotational speed. The immense centrifugal force expels the ethanol tincture from the biomass, passing it through the filter bag and out a discharge port. This phase continues until the maximum amount of solvent is recovered, leaving the biomass in a compact, nearly dry cake with residual solvent levels often below 3%.18

- Discharge: The separated, high-purity tincture is collected from the centrifuge outlet and is ready for the next stages of processing, such as solvent recovery and distillation. The “spent” biomass is then removed from the basket, and the centrifuge is ready for the next cycle.

This integrated process highlights a key advantage of modern extraction centrifuges: they represent a form of process compression. Instead of requiring separate vessels for soaking, pumps for transferring slurry, and presses for solvent recovery, the centrifuge combines extraction, washing, and liquid-solid separation into a single, highly efficient automated step.15 This consolidation not only reduces the equipment footprint and capital expenditure but also minimizes labor requirements, reduces the risk of product loss or contamination during transfers, and shortens the overall production timeline. By investing in a high-performance centrifuge, a facility is effectively simplifying and optimizing its entire downstream workflow.

III. The Buyer’s Blueprint: A Framework for Selecting Your Botanical Centrifuge

Making a sound investment in a botanical centrifuge requires a systematic evaluation of the equipment against four critical pillars: the intended scale of operation, the degree of process control required, adherence to regulatory and safety standards, and the fundamental engineering and durability of the machine. This framework provides a blueprint for decision-making, ensuring that the selected equipment is not only functional but also strategic.

Pillar 1: Scale of Operation – From R&D to Full Production

The operational goals of an extraction facility dictate the type of centrifuge required. A machine designed for high-volume production may be ill-suited for the nuanced work of research and development, and vice versa.

Research & Development (R&D) and Pilot Scale

At this scale, the primary objectives are process validation, the development of Standard Operating Procedures (SOPs), testing the extraction characteristics of new cannabis cultivars, and creating small, artisanal product batches.19 The focus is on data acquisition and process optimization, not raw throughput.

Consequently, the ideal R&D or pilot-scale centrifuge prioritizes flexibility. Essential features include highly variable speed control, adjustable timers for each cycle phase (agitation, spin dry), and the capacity to efficiently process small batch sizes without significant material loss.13 Advanced data logging capabilities to track parameters like temperature, speed, and cycle duration are highly beneficial for creating repeatable processes. A crucial function of a pilot-scale machine is its ability to accurately simulate the conditions of a larger production unit, which is fundamental for a successful and predictable scale-up to commercial manufacturing.19

Full-Scale Production

In a commercial production environment, the goals shift to maximizing throughput, ensuring batch-to-batch consistency, enhancing reliability, and automating processes to minimize labor costs.12 Downtime is a direct and significant loss of revenue, making equipment dependability the paramount concern.21

A production-scale centrifuge must be engineered for durability and continuous or near-continuous operation. Key requirements include a large batch capacity to process substantial amounts of biomass per cycle, the ability to generate high G-force for maximum solvent recovery, and seamless integration with ancillary facility systems like cryogenic chillers, pumps, and collection tanks. Automation via a Programmable Logic Controller (PLC) is standard, allowing for pre-programmed “recipes” that ensure every batch is run under identical, optimized conditions, guaranteeing a consistent final product.

Pillar 2: Process Control and Yield Optimization

The ability to precisely control every variable of the extraction process is what separates an average yield from a maximum, highly profitable one.

Temperature Control

As established, maintaining cryogenic temperatures is fundamental to a high-purity extraction. The centrifuge itself must be designed for this demanding environment. This requires more than just processing pre-chilled materials; it necessitates features like a jacketed housing that can be connected to a chiller to actively cool the centrifuge chamber and mitigate any heat generated by the motor during operation.22 Furthermore, all materials of construction, from the stainless steel to the seals and gaskets, must be rated for continuous operation at temperatures as low as -60°C to prevent material fatigue or failure.23 Precise and stable temperature control throughout the cycle is essential to prevent the degradation of heat-sensitive terpenes and to ensure consistent extraction efficiency batch after batch.10

Speed (RPM) vs. Force (RCF)

While often used interchangeably, RPM and RCF are distinct metrics. RPM measures the rotational speed of the motor, whereas RCF (Relative Centrifugal Force) is the actual measure of the separation force being applied to the contents of the basket. RCF is a function of both the rotational speed and the radius of the basket; therefore, a centrifuge with a larger diameter basket can generate the same RCF as a smaller basket while spinning at a lower RPM.25 When evaluating centrifuges, RCF (or G-force) is the more important specification. A higher RCF results in a more effective and complete removal of the ethanol tincture from the biomass, which directly increases solvent recovery and maximizes the yield of valuable cannabinoids.27

Cycle Time and Programmability

Optimizing the extraction process requires the ability to fine-tune the duration of each phase of the cycle. The ideal agitation time may vary depending on the density and particle size of the biomass, while the spin-dry duration impacts solvent recovery. A modern centrifuge equipped with a PLC and a human-machine interface (HMI), such as a touchscreen controller, provides this essential level of control. It allows operators to develop and save specific “recipes” or programs for different types of input material, ensuring perfect repeatability and consistent product quality with minimal operator intervention.16

Pillar 3: Regulatory Compliance and Operator Safety

As the cannabis industry matures, adherence to established safety and manufacturing standards is becoming a prerequisite for operation. This is particularly true when dealing with flammable solvents and producing products for human consumption.

Good Manufacturing Practices (GMP)

GMP is a system of regulations and guidelines enforced by agencies like the FDA to ensure that products are consistently produced and controlled according to quality standards. Adopting GMP is essential for ensuring product safety, batch-to-batch consistency, and for gaining access to more lucrative and demanding markets, including pharmaceutical applications and international export.2 A GMP-compliant centrifuge incorporates several key design principles:

- Material of Construction: All surfaces that come into contact with the product or solvent must be made from non-reactive, corrosion-resistant, and non-leaching materials. For this reason, 316L stainless steel is the industry standard for pharmaceutical and food-grade applications.2

- Sanitary Design: The interior of the process area must be designed to be easily and thoroughly cleaned. This means smooth, polished surfaces (often to a specific Ra value), rounded corners, and the elimination of crevices, threads, or “dead corners” where product could accumulate and harbor microbial growth.17

- Clean-in-Place (CIP): To ensure validated cleaning and prevent cross-contamination between different product batches, GMP-compliant centrifuges are equipped with CIP systems. These systems typically consist of strategically placed spray balls that can douse the entire internal process area with cleaning and sanitizing solutions, allowing for a fully automated and repeatable cleaning cycle without requiring equipment disassembly.31

Hazardous Location Rating (Class 1, Division 2 – C1D2)

Ethanol is a flammable solvent, and its vapors can create a potentially explosive atmosphere within a processing facility. Consequently, any electrical equipment operating in this environment must be appropriately rated to prevent it from becoming an ignition source. A Class 1, Division 2 (C1D2) rating is a non-negotiable safety and regulatory requirement for cannabis extraction centrifuges.11 This certification ensures that all electrical components, including the motor, control panel, and wiring, are designed to operate safely in an environment where flammable vapors may be present under abnormal conditions.23

While the primary market for these systems is often the United States, acknowledging international standards is a mark of a globally competitive manufacturer. For instance, in Mexico, industrial machinery safety is governed by Normas Oficiales Mexicanas (NOMs), such as NOM-004-STPS-1999, which covers protection and safety systems for machinery.36 A manufacturer that designs equipment with a global perspective ensures that their products can be deployed in expanding markets, a key strategic consideration for forward-thinking extraction businesses.1

Pillar 4: Engineering, Durability, and Maintenance

The long-term value of a centrifuge is directly tied to its fundamental engineering, the quality of its construction, and the ease with which it can be maintained.

Build Quality and “Legendary Dependability”

The immense forces generated during operation exert significant stress on a centrifuge’s mechanical components. A machine’s longevity and reliability—its dependability—are a direct result of robust engineering. Key indicators of high build quality include a heavy-gauge, rigid frame to dampen vibration, the use of oversized, high-quality bearings, and a meticulously engineered and dynamically balanced basket.1 These elements work in concert to ensure smooth operation, minimize wear and tear, and provide a service life that can be measured in decades, not years.

Material and Component Compatibility

Beyond the GMP requirement for 316L stainless steel, all other components must be compatible with the process conditions. This includes the elastomers used for seals and gaskets, such as EPDM, which must be rated for cryogenic temperatures and be chemically resistant to ethanol to prevent them from becoming brittle, failing, and causing leaks or product contamination.6

Ease of Maintenance and Vendor Support

Even the most robustly built machine requires routine maintenance. Thoughtful design can significantly reduce the time and complexity of these tasks. Features such as externally accessible grease fittings for bearings, simplified procedures for changing filter screens or bags, and the use of non-proprietary components that are readily available all contribute to minimizing downtime.27

Equally important is the level of post-sale support provided by the manufacturer. A strong vendor partnership includes comprehensive technical support, a readily available inventory of spare parts, and responsive emergency service. A manufacturer that offers 24/7 emergency support demonstrates a commitment to their customers’ operational continuity, a core component of long-term value.1

The following table provides a concise checklist summarizing these critical selection criteria, serving as an actionable tool for evaluating and comparing potential centrifuge solutions.

| Parameter | Requirement | Why It Matters |

| Scale of Operation | R&D / Pilot / Production | Matches machine capacity and features to business goals, from process development to high-throughput manufacturing. |

| Temperature Control | Cryogenic (-40°C or lower) | Ensures selective extraction of cannabinoids and terpenes, minimizing the need for downstream purification. |

| Max RCF | >1,000 xg | Higher G-force maximizes solvent recovery from biomass, directly increasing yield and profitability. |

| GMP Compliance | Yes | Essential for product safety, consistency, and access to pharmaceutical or international markets. |

| C1D2 Rating | Yes | A non-negotiable safety standard for operating with flammable solvents like ethanol. |

| Material of Construction | 316L SS / Compatible Elastomers | Prevents product contamination, ensures corrosion resistance, and guarantees material integrity at cryogenic temperatures. |

| CIP System | Yes | Allows for automated, validated cleaning to prevent cross-contamination, a core tenet of GMP. |

| PLC/Automation | Yes | Enables precise process control and repeatability, ensuring consistent product quality and reducing labor costs. |

| Vendor Support | 24/7 Service / Parts Availability | Minimizes costly downtime and ensures the long-term operational viability of the investment. |

IV. Beyond the Sticker Price: Analyzing Total Cost of Ownership (TCO) and ROI

A common and costly pitfall in purchasing industrial equipment is focusing narrowly on the initial acquisition price. For capital equipment like a production-scale centrifuge, the upfront cost typically represents only a small fraction—often less than 20-30%—of its Total Cost of Ownership (TCO) over its operational lifespan.28 A strategic evaluation must shift the paradigm from short-term price to long-term value. This approach, which analyzes all direct and indirect costs over the life of the asset, is where the true financial impact of a purchasing decision is revealed and where the value of robust engineering and “Legendary Dependability” becomes a quantifiable economic advantage.1

By providing a framework for TCO and Return on Investment (ROI), the conversation shifts from a simple vendor-buyer transaction to a consultative partnership. This empowers the facility’s decision-makers to build a robust business case, justifying a potentially higher initial investment by demonstrating a significantly lower TCO and a faster, more substantial ROI. This reframes the definition of “cost” from a one-time expense to a long-term strategic calculation of profitability.

The Components of Total Cost of Ownership (TCO)

A comprehensive TCO analysis for a botanical centrifuge includes several key cost categories 41:

- Acquisition Cost (Ca): This is the most straightforward component, encompassing the purchase price of the centrifuge, as well as associated costs for shipping, installation, and commissioning.

- Operating Costs (Co): These are the recurring expenses required to run the machine. Key factors include:

- Energy Consumption: Centrifuges are powerful machines. Models equipped with modern, high-efficiency motors and Variable Frequency Drives (VFDs) can significantly reduce electricity consumption compared to older or less advanced designs.42

- Solvent Loss: The efficiency of the spin-dry cycle directly impacts how much costly ethanol is retained in the “spent” biomass. A high-performance centrifuge that achieves >97% solvent recovery minimizes this recurring operational expense.18

- Labor: A fully automated centrifuge with programmable cycles can be managed by a single operator, drastically reducing the labor cost per pound of processed biomass.22

- Maintenance Costs (Cm): This includes the cost of routine preventive maintenance, consumable parts like seals and filter bags, and any necessary repairs. A robustly engineered machine with high-quality components will naturally have lower maintenance costs and a longer Mean Time Between Failures (MTBF) than a less durable alternative.41

- Downtime Costs (Cd): This is the most critical and frequently underestimated component of TCO. Unplanned downtime due to equipment failure results in a complete halt in production. The cost of downtime is the value of the lost production for every hour the machine is offline. For a full-scale production facility, this can easily amount to tens of thousands of dollars per day, meaning a single significant failure can quickly erase any savings realized from a lower initial purchase price.28 This is where the financial value of “Legendary Dependability” is most evident.

Calculating Your Return on Investment (ROI)

While TCO analyzes the total cost, ROI measures the profitability of the investment. It calculates how long it will take for the equipment to pay for itself and the total profit it will generate over its life. A basic formula for ROI is 45:

ROI(%)=Cost of InvestmentNet Profit×100

Where:

- Cost of Investment is the total acquisition cost (Ca).

- Net Profit is the financial gains generated by the equipment minus its total operating and maintenance costs over a specific period.

The gains from a high-performance centrifuge are multi-faceted:

- Increased Yield: Superior process control and higher G-force extraction lead to a greater quantity of cannabinoids recovered from each batch of biomass.

- Enhanced Throughput: Optimized, automated cycles and high reliability allow for more batches to be processed per shift, increasing the facility’s total output capacity.

- Reduced Operating Expenses: As detailed in the TCO analysis, savings on energy, solvent, and labor directly contribute to higher net profit.

- Improved Product Quality: The ability to consistently produce a high-purity extract can command a premium price in the market, further boosting revenue.

The Western States TCO Advantage

An investment in a Western States centrifuge is a strategic decision to secure the lowest possible Total Cost of Ownership. The synthesis of over a century of industrial engineering experience, the use of high-strength alloys and premium components, and a design philosophy centered on durability minimizes maintenance and downtime costs.1 Simultaneously, the integration of advanced automation and high-efficiency drives reduces operating costs. This combination, backed by unparalleled 24/7 customer support, ensures that the equipment delivers the highest possible long-term value and a rapid, sustainable return on investment.40

V. Sizing Your Solution: Matching Western States Models to Your Mission

With a clear understanding of the selection framework and economic considerations, the final step is to apply this knowledge to the specific solutions available. The Western States line of botanical centrifuges is engineered to meet the distinct needs of every stage of the extraction journey, from initial research to full-scale industrial production.

Model Breakdown: From Lab Bench to Production Floor

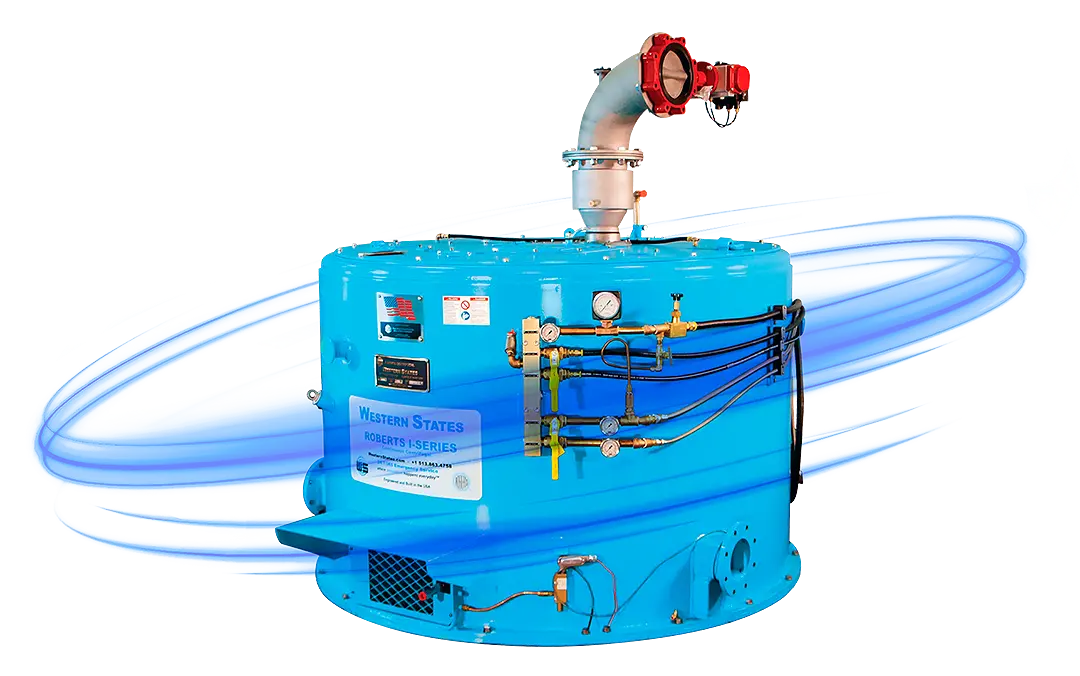

- WSB-MicroPro: The R&D and Process Development Engine

The WSB-MicroPro is engineered as the ideal solution for Research & Development, process validation, and academic labs. Its compact footprint and ability to handle small batch sizes make it perfect for environments where flexibility and data generation are the primary goals. This model allows operators to test extraction parameters on new cultivars, develop and refine SOPs, and validate a process with minimal material consumption before committing to a larger scale.1 It is the essential first step in building a scalable, data-driven extraction operation. - WSB-15: The Pilot-Scale and Boutique Production Bridge

The WSB-15 serves as the critical bridge between R&D and full-scale manufacturing, making it the premier choice for pilot-scale operations and small-batch commercial production. With a capacity to process up to 15 lbs of biomass per cycle, it allows businesses to scale up their output confidently, produce high-value artisanal or boutique products, and meet initial market demand without the capital investment of a larger production machine.22 It embodies the transition from process development to profitable production. - WSB-40: The Full-Scale Production Workhorse

The WSB-40 is the definitive full-scale production centrifuge, designed for the rigors of continuous, high-throughput industrial manufacturing. Its substantial capacity of up to 40 lbs of biomass per 10–20 minute cycle provides the output necessary for large-scale commercial operations.22 Built upon a foundation of industrial durability, the WSB-40 is engineered for maximum uptime, efficiency, and reliability, making it the cornerstone asset for facilities focused on maximizing production and profitability.1

Process Validation Support (IQ/OQ/PQ)

Recognizing the industry’s trajectory towards pharmaceutical-grade standards, Western States provides comprehensive documentation and support for process validation. For clients operating under or implementing GMP, this support is critical for Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). This ensures that the equipment is installed correctly, operates according to specifications, and consistently produces a product that meets predefined quality attributes. This level of validation support is a high-value service that de-risks the implementation process and ensures the equipment can be seamlessly integrated into a fully compliant manufacturing environment.46

The following table provides a direct, side-by-side comparison of the Western States botanical centrifuge line, offering the technical data required for an informed selection.

| Specification | WSB-MicroPro | WSB-15 | WSB-40 |

| Target Application | R&D, Process Validation | Pilot Scale, Small-Batch Production | Full-Scale Industrial Production |

| Biomass Capacity | Custom (Small Scale) | Up to 15 lbs / 6.8 kg per cycle | Up to 40 lbs / 18.1 kg per cycle |

| Avg. Cycle Time | 10–20 minutes | 10–20 minutes | 10–20 minutes |

| Max RCF | >1,000 xg | >1,000 xg | >1,000 xg |

| Motor | C1D2 Rated | C1D2 Rated | C1D2 Rated |

| Materials of Construction | 316L SS Contact Parts | 316L SS Contact Parts | 316L SS Contact Parts |

| GMP Compliant Design | Yes | Yes | Yes |

| Control System | PLC with HMI | PLC with HMI | PLC with HMI |

VI. The Western States Advantage: A Century of Engineering for Your Peace of Mind

Choosing a centrifuge is a critical strategic decision that reverberates throughout an extraction facility, profoundly impacting product quality, operational safety, regulatory compliance, and long-term profitability. The selection process demands a holistic view that looks beyond the initial price tag to evaluate the engineering integrity, process control capabilities, and lifetime value of the equipment. The framework provided in this guide offers a clear path to making a decision that is not just technically sound but also financially astute.

Ultimately, the choice of a manufacturing partner is as important as the choice of the machine itself. The Western States advantage is built upon three foundational pillars that directly address the core concerns of the modern botanical extractor.

- Legendary Dependability: With a history of engineering and manufacturing centrifuges that dates back to 1917, and with machines from the 1950s still in service globally, Western States brings an unparalleled legacy of industrial durability. This is not a new venture into a trending market; it is the application of a century of proven, robust engineering principles to meet the demanding needs of the botanical extraction industry. This history is the ultimate proof of a low Total Cost of Ownership.1

- Superior Customer Service: The commitment to a customer’s success extends far beyond the point of sale. A partnership with Western States includes access to a 24/7 emergency service hotline, an extensive on-site inventory of replacement parts for immediate shipment, and a dedicated team of experienced service technicians. This comprehensive support infrastructure is a promise of operational continuity and true partnership.1

- American-Made Quality: Every Western States centrifuge is manufactured in the USA, ensuring the highest standards of quality control, materials sourcing, and supply chain reliability. This is both a point of pride and a tangible assurance of the quality and integrity built into every machine.40

Your extraction process is unique, and your equipment solution should be tailored to match. The path to optimizing your facility’s performance and profitability begins with a conversation.

Contact a Western States extraction expert today to discuss your specific requirements and configure the ideal centrifuge solution to drive your facility’s success.