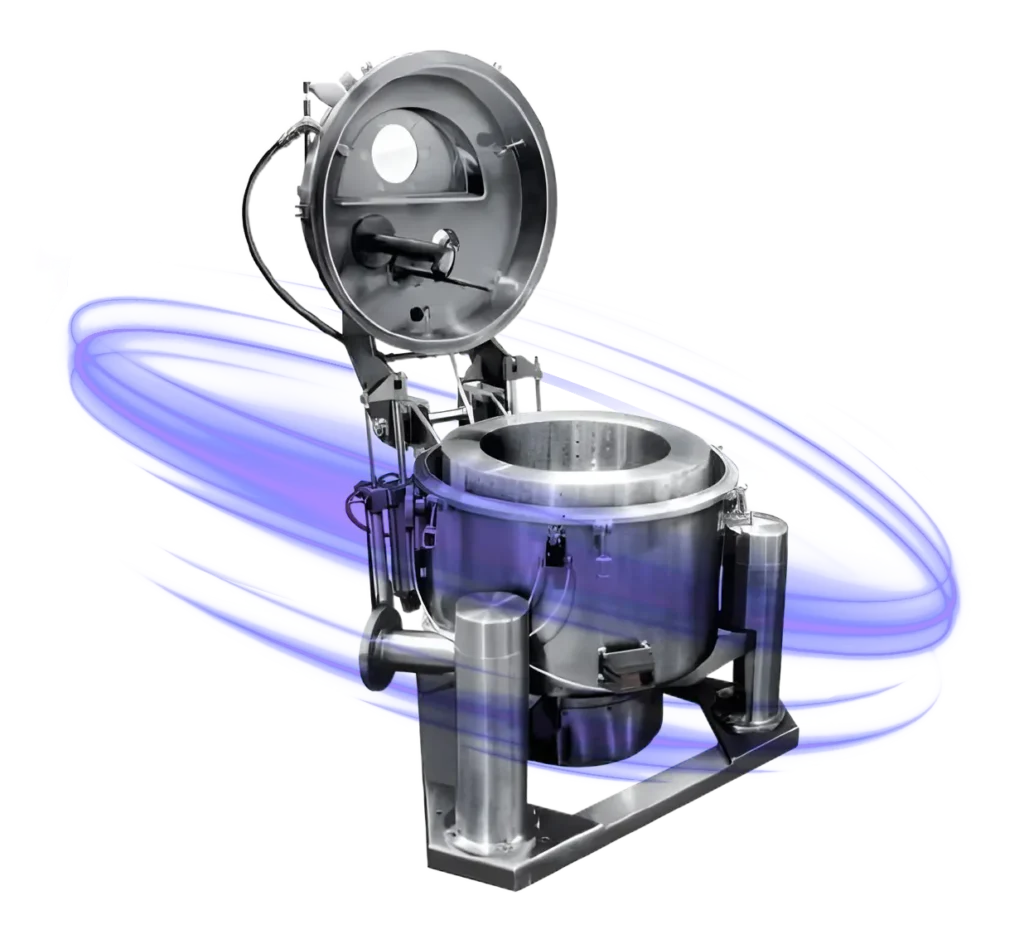

Quadramatic Centrifuge Overview

- Vertical design with bottom-discharge or top-unload options.

- Generates up to 2,000 gravities of separation force.

Key Features & Benefits

Thermal-free operation: Removes nearly all unbound moisture without heat, reducing energy costs.

Scalable: Capacities range from 1.9 ft³ to 33 ft³, adaptable for medium to full-scale production.

- Continuous, automatic operation: Engineered for reliability and minimal downtime.

Applications

Cost-effective solid-liquid separation in diverse chemical industries.

Ideal for high-volume, dependable filtration processes.

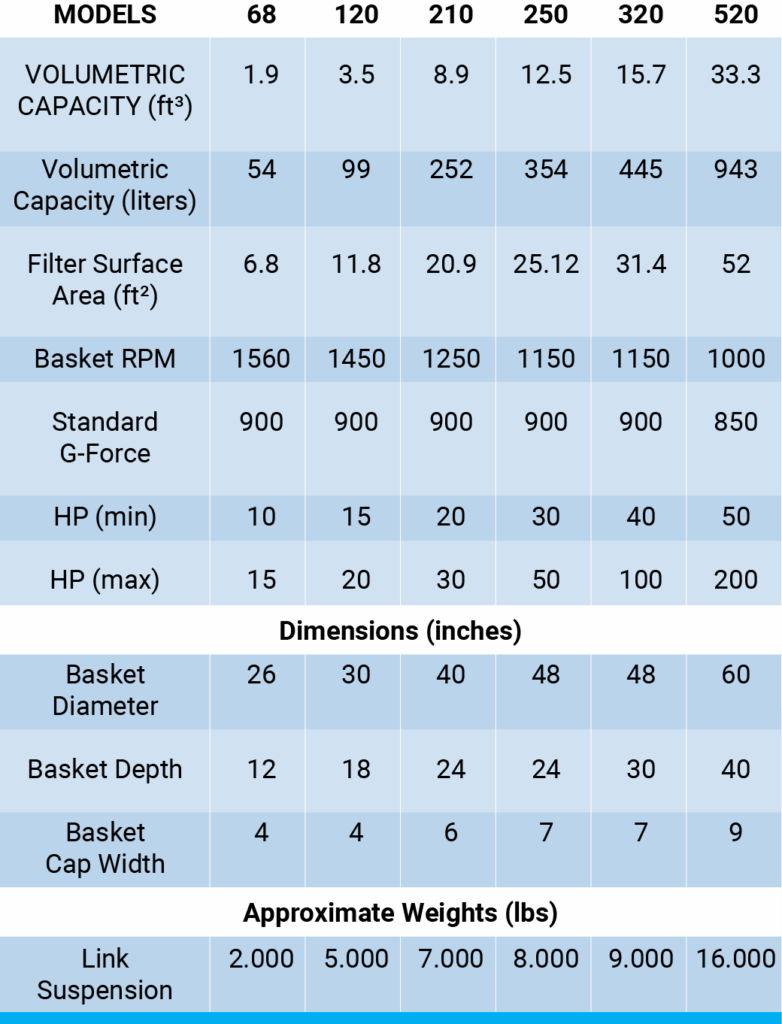

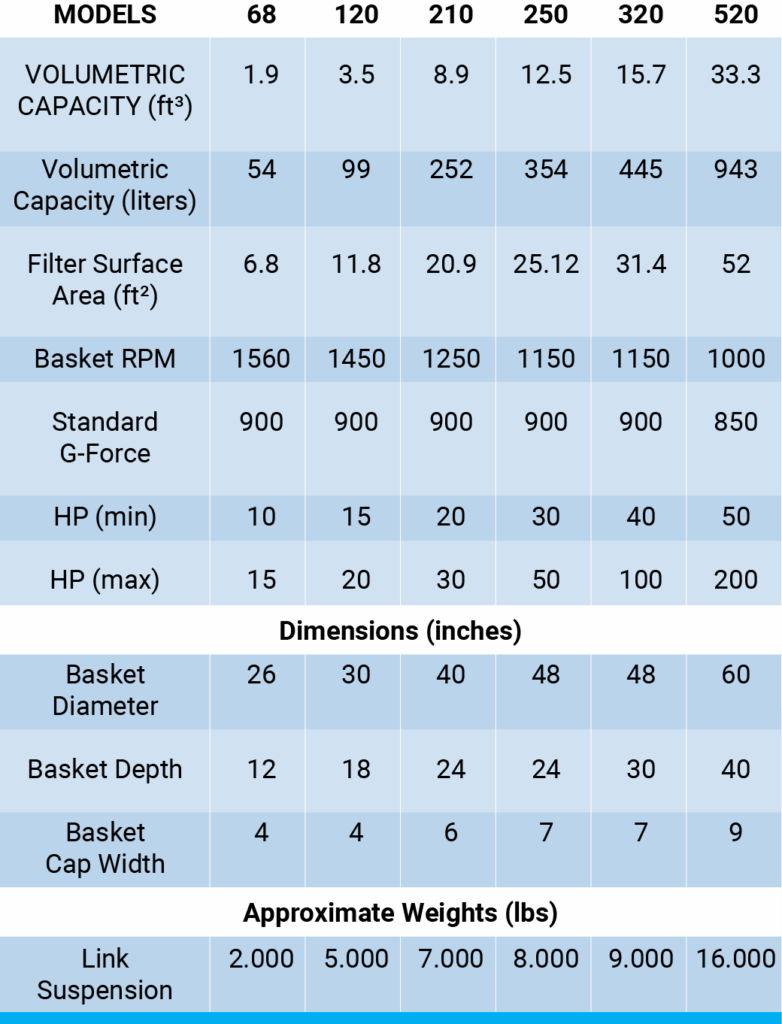

QUADRAMATIC TECHNICAL DATA

Material options

- 316 Stainless Steel

- 904 Stainless Steel

- Duplex Hastelloy C-22

- Others

Coating options

- Halar

- PTFE

- Ebonite

- Other

Design Features

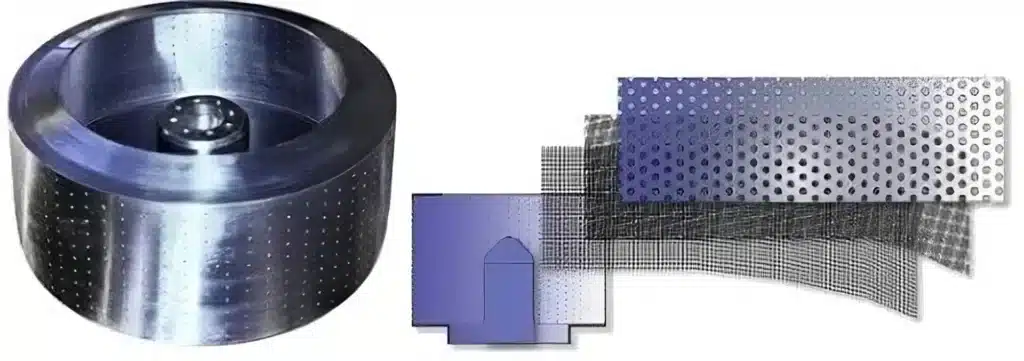

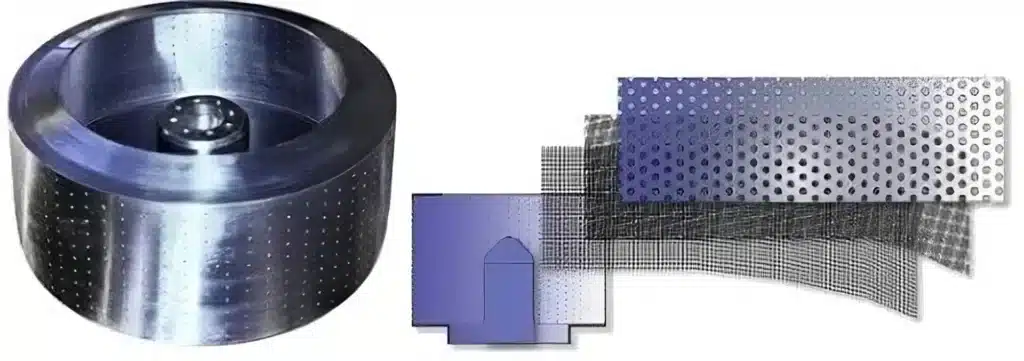

Basket

Advanced Separation Technology

- Highly perforated filter basket prevents “water wall” formation and minimizes excessive gyration.

- Efficient liquid purging for maximum loading capacity.

Safety & Durability

- 2.0 Safety Factor (industry-leading safety standard).

- Fully machined, parallel internal/external surfaces on basket side sheets and bowl walls.

- Seam X-ray inspected and dynamically balanced for optimal performance at 900+ G-force.

Customizable Filtration

- Filter media (backing layers, plow plates) tailored to create specialized basket systems for unique product needs.

Key Benefits

- Reliable, high-performance operation in demanding industrial applications.

- Combines precision engineering with adaptable design for diverse separation tasks.

Load Sensor

Patented Ultrasonic Load Control System

Precisely monitors/controls feed rate and cake depth to optimize separation performance.

Non-invasive design: No moving parts; never contacts the cake for reliable, maintenance-free operation.

Key Benefits

- Ensures maximum discharge of high-value solids, minimizing product loss.

- Enhances process efficiency and reliability in critical separation tasks.

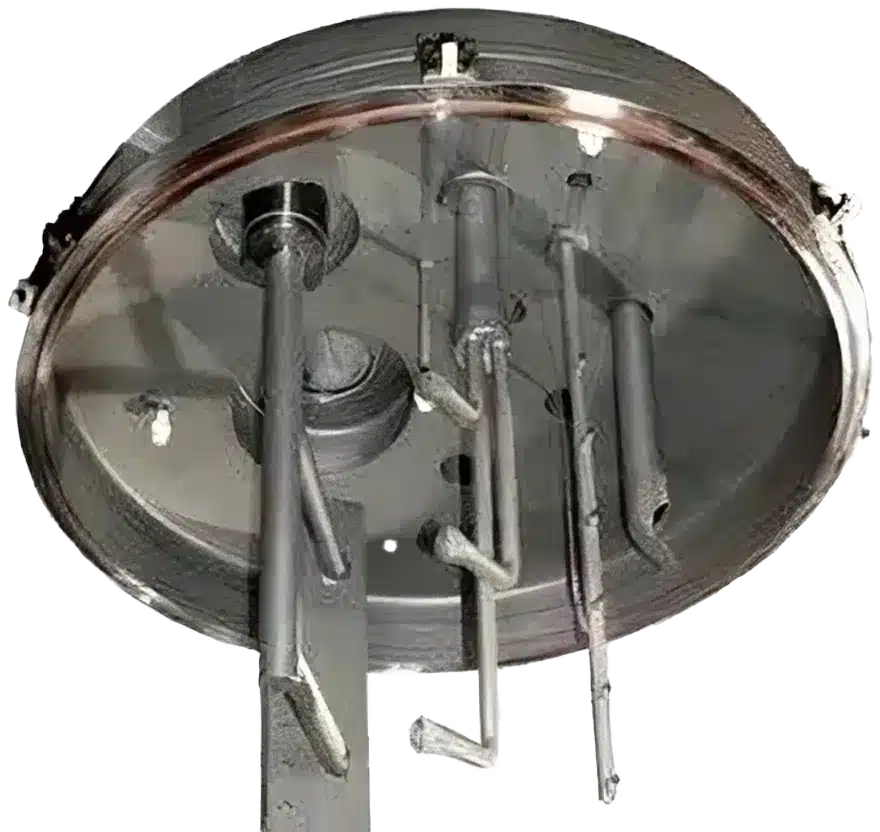

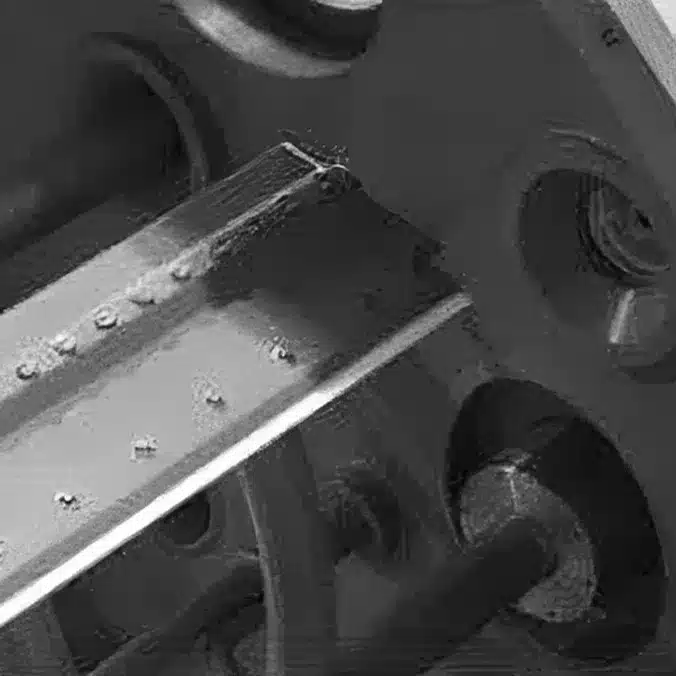

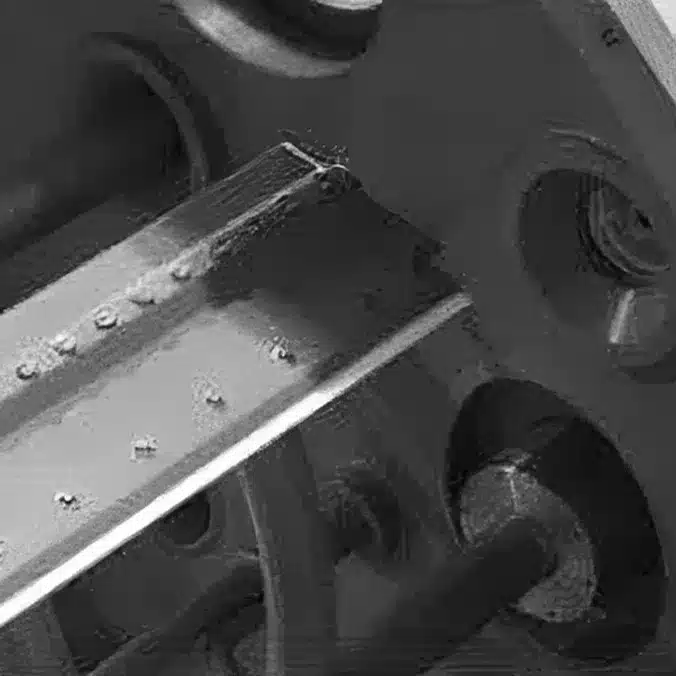

Discharger

Monocut Discharger

Features a full-length plow blade with a replaceable cutting tip.

Removes sedimentation in a single horizontal inward motion, simplifying operation.

Eliminates vertical seals (common contamination sources), reducing maintenance and contamination risks.

Optional Heel Removal System:

- Uses air to assist in removing residual product cake, ensuring maximum solids recovery.

- Enhances separation efficiency and minimizes product waste.

Ease of Maintenance

Vertical Tapered Basket Spindle & Bearings

Engineered for high strength, stability, and long-term durability.

Simplified maintenance design with heavy-duty ball/roller bearings.

Easy Lubrication System

- Grease fittings externally positioned for quick, tool-free lubrication.

Extended Bearing Protection

- Sealed housing purged with clean air/inert gas to prevent contamination and prolong bearing life.

OTHER AVAILABLE DESIGN FEATURES

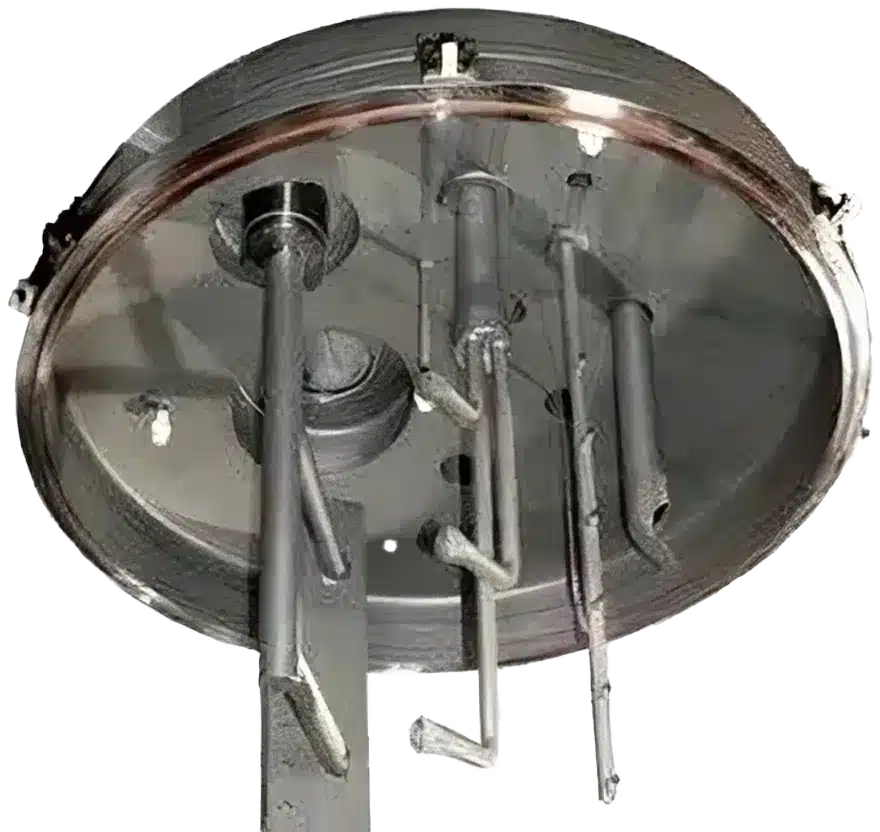

Access Cover Options

Full-opening hydraulic hinged domed cover for optimal inspection and user accessibility.

Fume-tight construction; configurable as pressure or vacuum vessels for specialized applications.

Safety & Compatibility

Designed to handle volatile, explosive, or toxic materials safely.

Oxygen sensors ensure inert gas blanketing, maintaining safe residual oxygen levels.

Optional Accessories

- Sight glass, fume vent, custom feed/wash pipes, and Quadramatic™ CIP Option (clean-in-place).

STANDARD AVAILABLE OPTIONS

QUADRA-CLEAN AND QUADRAMATIC

MATERIALS OF CONSTRUCTION

Customizable Construction & Filter Media

Materials and filter mediums tailored to meet specific customer needs.

Material Options

Product-contact components (baskets, etc.)

Metals: Stainless steels, nickel alloys (Inconel, Monel, Hastelloy), titanium, duplex stainless, and exotic alloys.

Linings: Rubber, elastomers.

Coatings: HALAR®, TEFLON®, and other advanced protective finishes.

Surface Finishes

Range from satin bead blast to mechanical/electrochemical polishing (mirror-like finish) for sanitary or high-purity applications.

Quality Assurance

All internal/external welds exceed applicable industry standards.

CIP SYSTEM

CIP System (Clean-in-Place)

- Cleans the centrifuge process zone between batches or product changes, ensuring hygiene.

- Even coverage: Strategically placed nozzles spray all surfaces; upper sections saturated during basket rotation, lower sections flooded.

Key Benefits

- Eliminates cross-contamination risks in Western States vertical centrifuges.

- Validated performance: Riboflavin Test during Factory Acceptance Test (FAT) confirms full cleaning solvent contact on all surfaces.

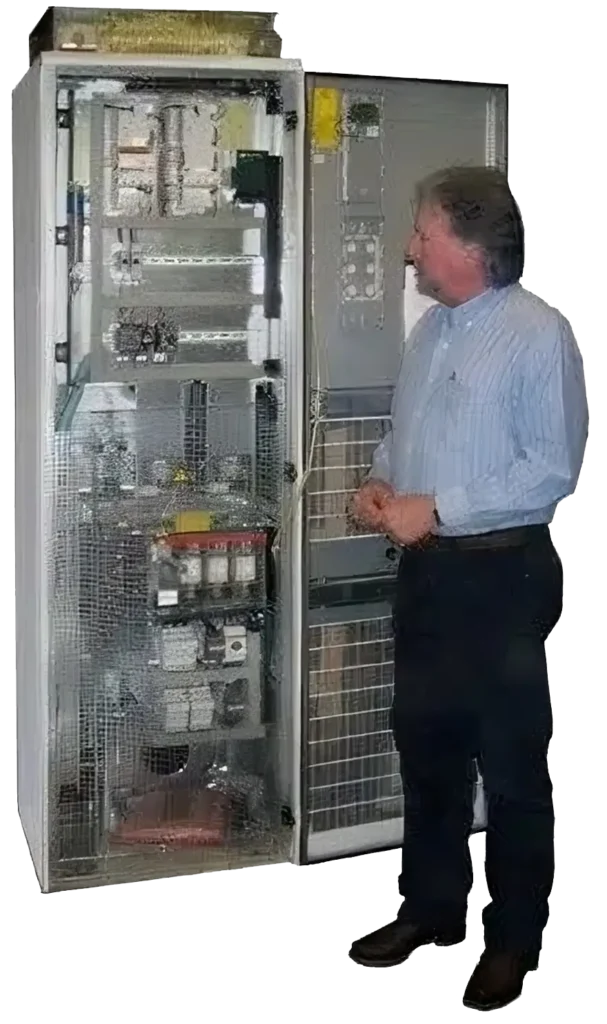

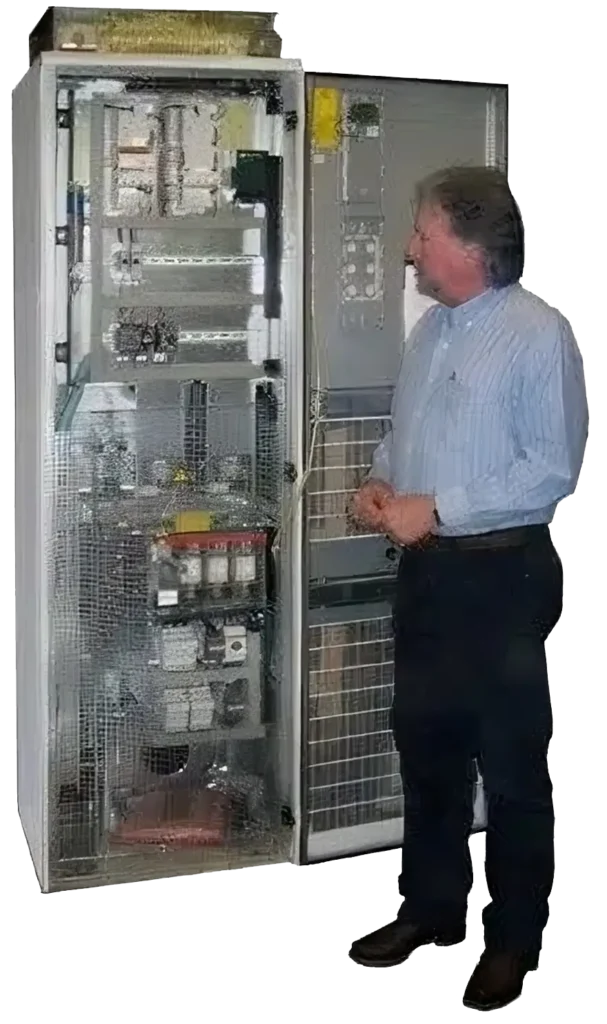

AUTOMATION & CONTROLS

Automation & Control Systems

- Leader in programmable control systems and variable frequency drives for centrifuge automation.

- State-of-the-art components tailored to diverse needs, enabling maximum processing flexibility and ultrafiltration.

Operating Modes

- Fully automatic (PLC-driven) to manual control options.

Safety & Compliance

NEMA enclosures available, including explosion-proof designs (Class I, Division I, Groups C & D rated).

Thermal-Free Precision.

Scalable for Every Revolution

- Quadramatic Centrifuge Overview

Vertical design with bottom-discharge or top-unload options.

Generates up to 2,000 gravities of separation force.

- Key Features & Benefits:

Thermal-free operation: Removes nearly all unbound moisture without heat, reducing energy costs.

Scalable: Capacities range from 1.9 ft³ to 33 ft³, adaptable for medium to full-scale production.

Continuous, automatic operation: Engineered for reliability and minimal downtime.

- Applications

Cost-effective solid-liquid separation in diverse chemical industries.

Ideal for high-volume, dependable filtration processes.

QUADRAMATIC

TECHNICAL DATA

- Material options

- 316 Stainless Steel

- 904 Stainless Steel

- Duplex Hastelloy C-22

- Others

- Coating options

- Halar

- PTFE

- Ebonite

- Other

Design

Features

Basket

- Advanced Separation Technology

- Highly perforated filter basket prevents “water wall” formation and minimizes excessive gyration.

- Efficient liquid purging for maximum loading capacity.

- Safety & Durability

- 2.0 Safety Factor (industry-leading safety standard).

- Fully machined, parallel internal/external surfaces on basket side sheets and bowl walls.

- Seam X-ray inspected and dynamically balanced for optimal performance at 900+ G-force.

- Customizable Filtration

- Filter media (backing layers, plow plates) tailored to create specialized basket systems for unique product needs.

- Key Benefits

- Reliable, high-performance operation in demanding industrial applications.

- Combines precision engineering with adaptable design for diverse separation tasks.

Load Sensor

- Patented Ultrasonic Load Control System

Precisely monitors/controls feed rate and cake depth to optimize separation performance.

Non-invasive design: No moving parts; never contacts the cake for reliable, maintenance-free operation.

- Key Benefits

- Ensures maximum discharge of high-value solids, minimizing product loss.

- Enhances process efficiency and reliability in critical separation tasks.

Discharger

- Monocut Discharger

Features a full-length plow blade with a replaceable cutting tip.

Removes sedimentation in a single horizontal inward motion, simplifying operation.

Eliminates vertical seals (common contamination sources), reducing maintenance and contamination risks.

- Optional Heel Removal System:

- Uses air to assist in removing residual product cake, ensuring maximum solids recovery.

- Enhances separation efficiency and minimizes product waste.

Ease of Maintenance

- Vertical Tapered Basket Spindle & Bearings

Engineered for high strength, stability, and long-term durability.

Simplified maintenance design with heavy-duty ball/roller bearings.

- Easy Lubrication System

- Grease fittings externally positioned for quick, tool-free lubrication.

- Extended Bearing Protection

- Sealed housing purged with clean air/inert gas to prevent contamination and prolong bearing life.

OTHER AVAILABLE

DESIGN FEATURES

- Access Cover Options

Full-opening hydraulic hinged domed cover for optimal inspection and user accessibility.

Fume-tight construction; configurable as pressure or vacuum vessels for specialized applications.

- Safety & Compatibility

Designed to handle volatile, explosive, or toxic materials safely.

Oxygen sensors ensure inert gas blanketing, maintaining safe residual oxygen levels.

- Optional Accessories

Sight glass, fume vent, custom feed/wash pipes, and Quadramatic™ CIP Option (clean-in-place).

STANDARD

AVAILABLE

OPTIONS

QUADRA-CLEAN AND QUADRAMATIC

MATERIALS OF CONSTRUCTION

- Customizable Construction & Filter Media

Materials and filter mediums tailored to meet specific customer needs.

- Material Options

Product-contact components (baskets, etc.)

Metals: Stainless steels, nickel alloys (Inconel, Monel, Hastelloy), titanium, duplex stainless, and exotic alloys.

Linings: Rubber, elastomers.

Coatings: HALAR®, TEFLON®, and other advanced protective finishes.

- Surface Finishes

Range from satin bead blast to mechanical/electrochemical polishing (mirror-like finish) for sanitary or high-purity applications.

- Quality Assurance

All internal/external welds exceed applicable industry standards.

CIP SYSTEM

- CIP System (Clean-in-Place)

- Cleans the centrifuge process zone between batches or product changes, ensuring hygiene.

- Even coverage: Strategically placed nozzles spray all surfaces; upper sections saturated during basket rotation, lower sections flooded.

- Key Benefits

- Eliminates cross-contamination risks in Western States vertical centrifuges.

- Validated performance: Riboflavin Test during Factory Acceptance Test (FAT) confirms full cleaning solvent contact on all surfaces.

AUTOMATION & CONTROLS

- Automation & Control Systems

- Leader in programmable control systems and variable frequency drives for centrifuge automation.

- State-of-the-art components tailored to diverse needs, enabling maximum processing flexibility and ultrafiltration.

- Operating Modes

Fully automatic (PLC-driven) to manual control options.

- Safety & Compliance

NEMA enclosures available, including explosion-proof designs (Class I, Division I, Groups C & D rated).