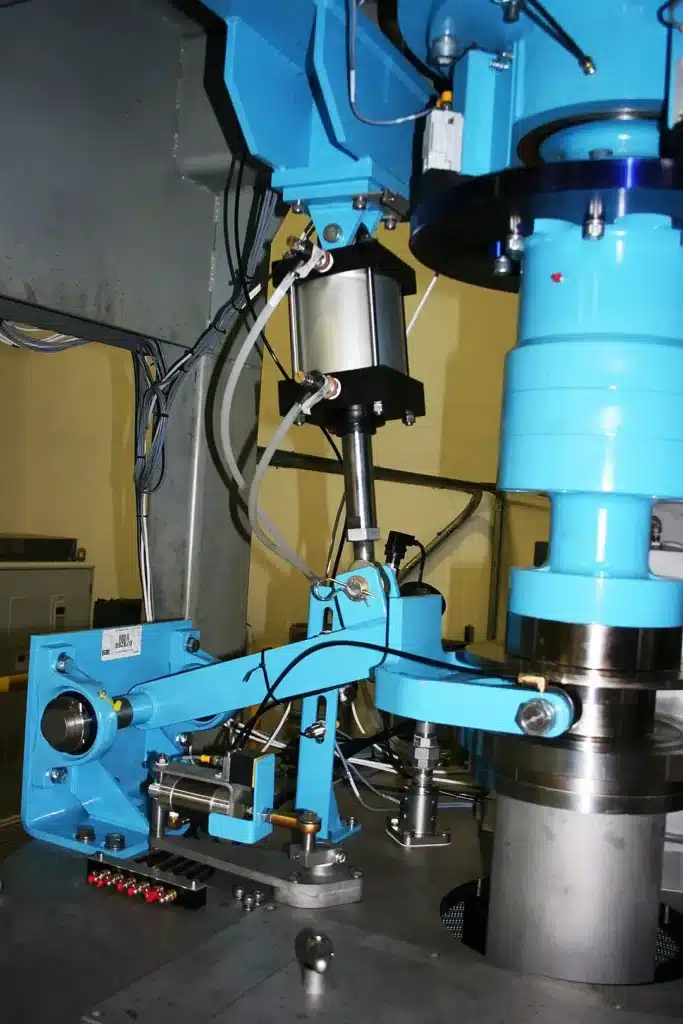

The Roberts G-16 LINC Batch Sugar Centrifugal has many advantages over your existing G-8 style batch centrifuge by incorporating modern components borrowed from the latest technology of the TITAN® Batch Centrifuges. This batch sugar centrifuge is designed to fit in the structural steel of your existing G-8, effectively cutting the cost of building a new structure, and linking the footprint of the past to the technology of today!

WHY CHOOSE THE ROBERTS G-16 LINC BATCH CENTRIFUGAL?

Engineering Excellence & Durability

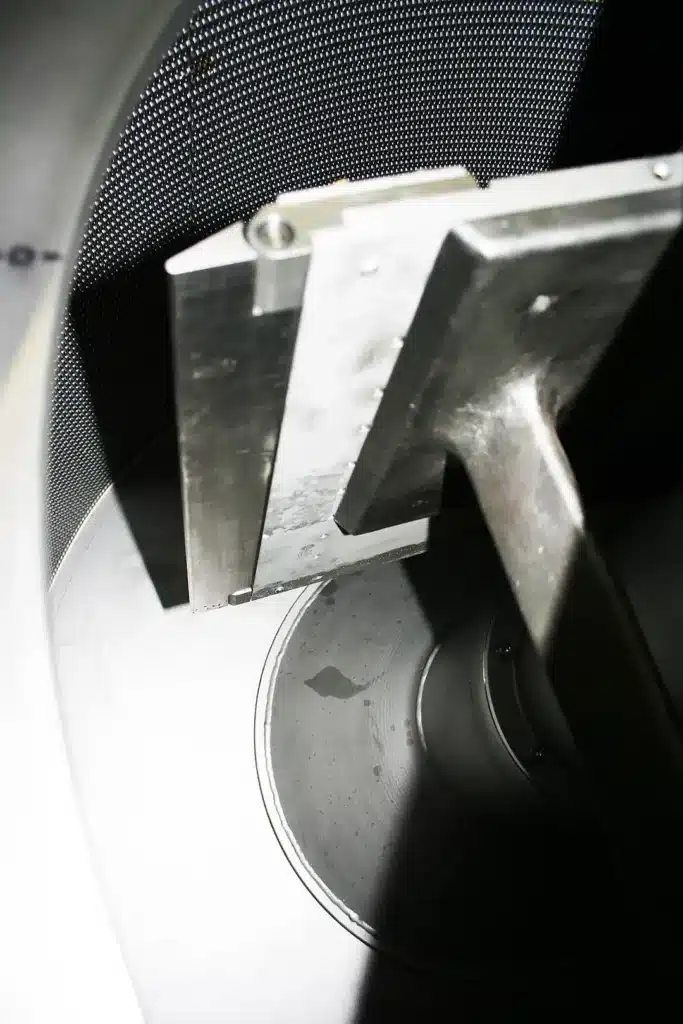

Unobstructed download

Downward opening spring basket valve which allows for unobstructed sugar discharging

Time saving

Duplex stainless steel ringless baskets take less time to inspect

Waste reduction

RD-3 Discharger robust design for minimal sugar loss

Increase the capacity

Of the larger ringless baskets

Precise batches

Precision paddle load control ensures accurate and consistent batches

Troubleshooting

Locally mounted Allen-Bradley Micrologix 1400 PLC includes built-in diagnostics and troubleshooting

LCD touch screen

Allen Bradley Panelview Plus Compact 1000 10.4″ color LCD touchscreen displays cycle information, help screens and tracks maintenance hour intervals, maintains alarm logs and tracks centrifuge performance information

Maximum protection

Completely guarded to meet OSHA standard

ROBERTS G-16 LINC TECHNICAL DATA

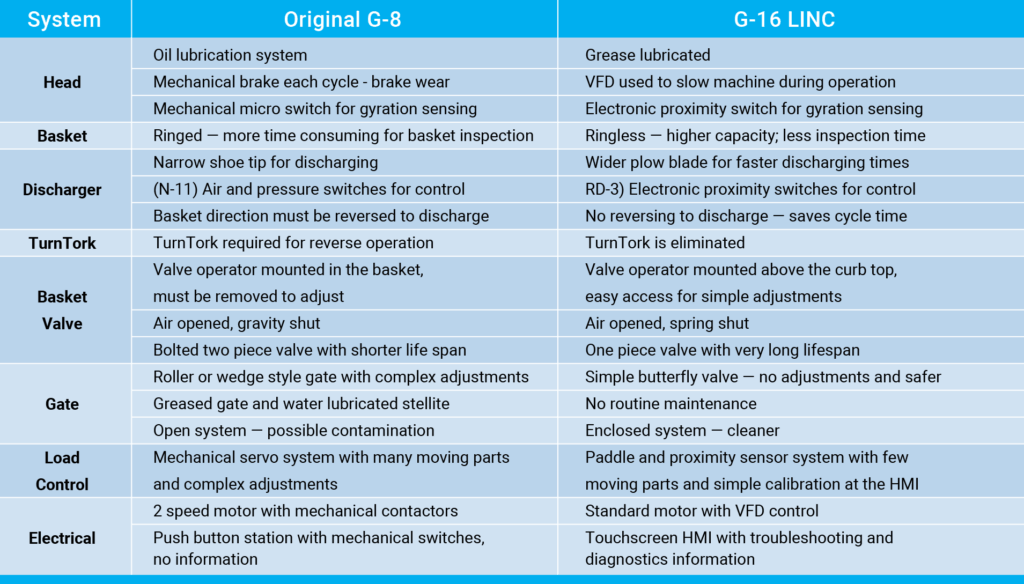

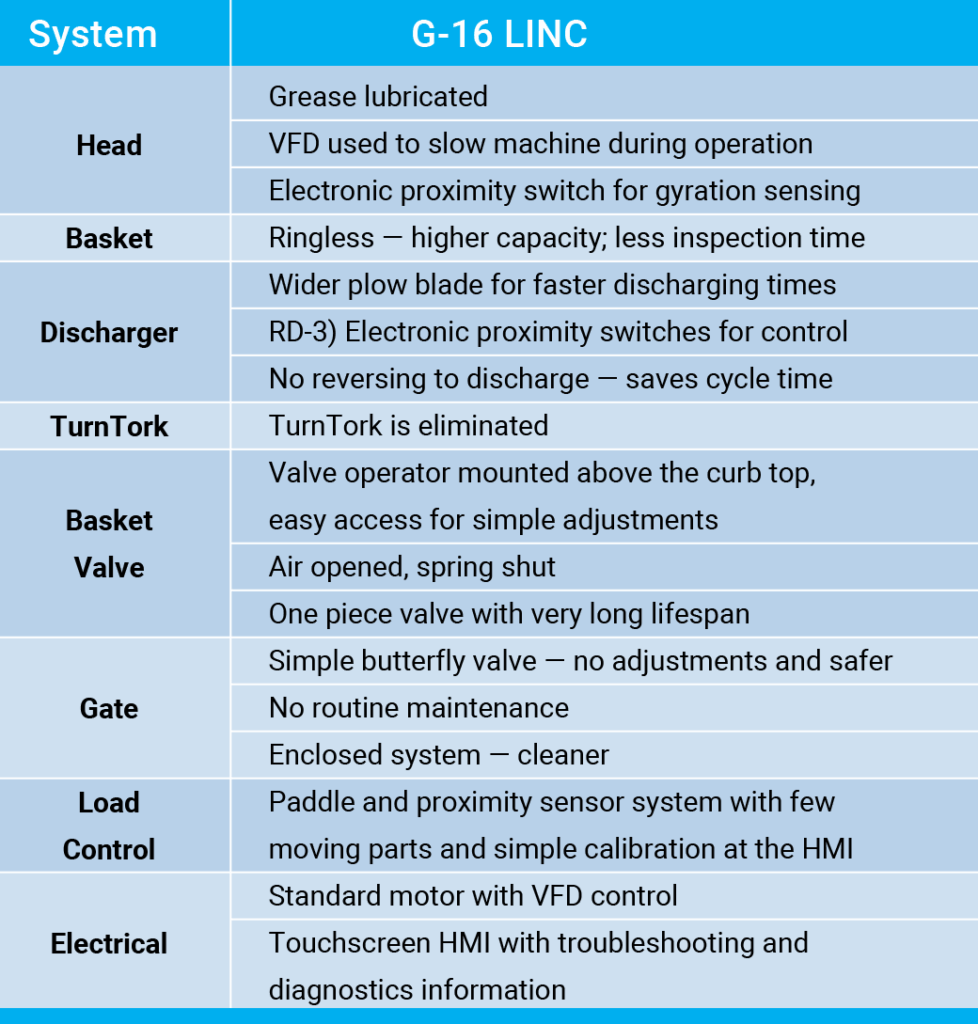

Original G-8 to G-16 LINC Maintenance Comparison

Centrifugals overall dimensions

Maximize Capacity, Minimize Loss

The Roberts G-16 LINC Batch Sugar Centrifugal has many advantages over your existing G-8 style batch centrifuge by incorporating modern components borrowed from the latest technology of the TITAN® Batch Centrifuges. This batch sugar centrifuge is designed to fit in the structural steel of your existing G-8, effectively cutting the cost of building a new structure, and linking the footprint of the past to the technology of today!

WHY CHOOSE THE ROBERTS G-16 LINC BATCH CENTRIFUGAL?

- Unobstructed download

Downward opening spring basket valve which allows for unobstructed sugar discharging

- Time saving

Duplex stainless steel ringless baskets take less time to inspect

- Waste reduction

RD-3 Discharger robust design for minimal sugar loss

- Increase the capacity

Of the larger ringless baskets

- Precise batches

Precision paddle load control ensures accurate and consistent batches

- Troubleshooting

Locally mounted Allen-Bradley Micrologix 1400 PLC includes built-in diagnostics and troubleshooting

- LCD touch screen

Allen Bradley Panelview Plus Compact 1000 10.4″ color LCD touchscreen displays cycle information, help screens and tracks maintenance hour intervals, maintains alarm logs and tracks centrifuge performance information

- Maximum protection

Completely guarded to meet OSHA standard

ROBERTS G-16 LINC

TECHNICAL DATA

Original G-8 to G-16 LINC Maintenance Comparison

Centrifugals

overall dimensions