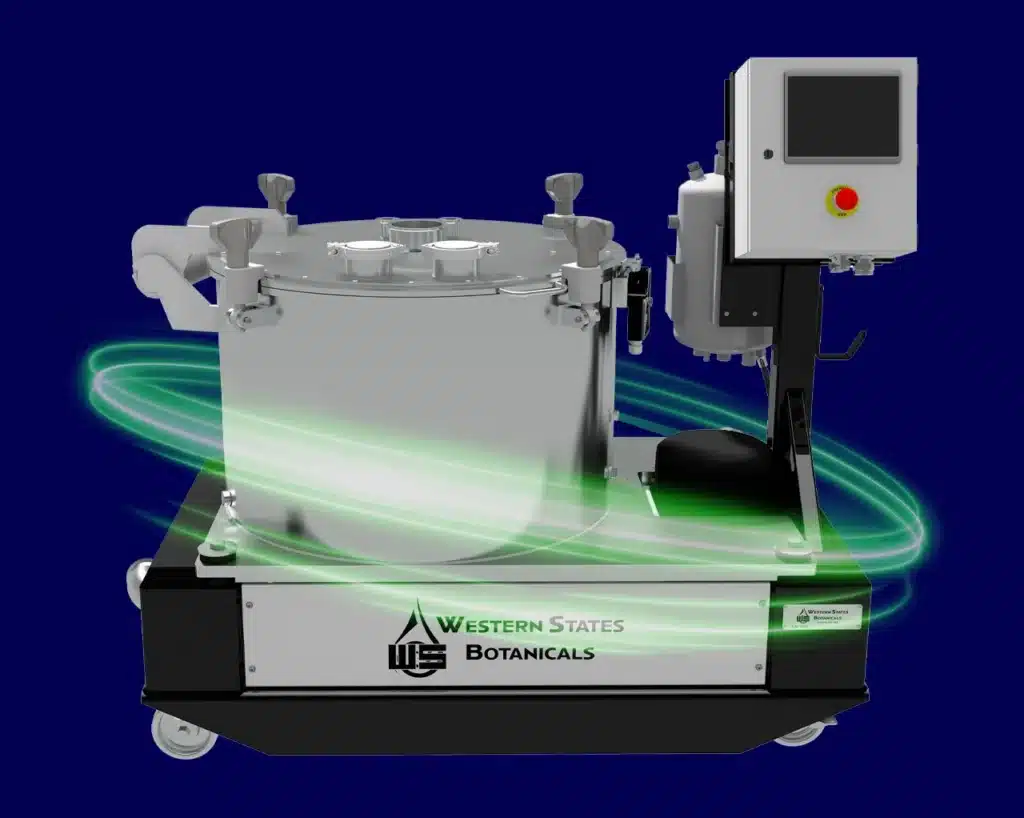

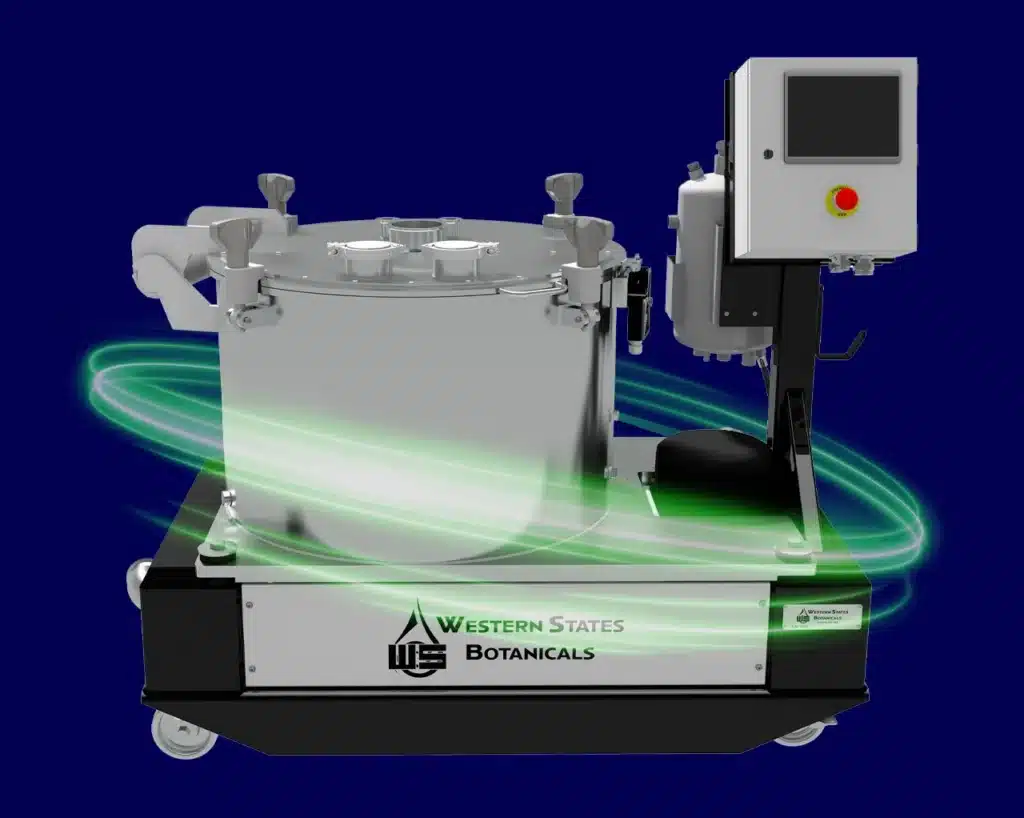

The WSB-40 is designed for the maximum extraction of desired molecules

and is suitable for mid to large scale production volumes.

This machine can handle up to 40 pounds per 10-to-20-minute cycle

and boasts 98% removal of the desired molecules

Technical Specifications

General

- 1561 RPM

- 900 Gs

- 133 liter volumetric capacity

- 40 lb maximum biomass load

- 7.2 ft 3 flood volume

- -40°F Minimum operating temperature, 104°F Maximum operating temperature. (32°F to 104°F Ambient)

Curb

- 304L stainless steel construction with internal vacuum/fluid jacket that covers the entire height of the curb

- Vacuum/fluid jacket supplied with (2) 1/2” NPT connections

- 1-1/4” inertia pad curb floor includes a 3” sanitary fitting for effluent outlet

- Jacket pressure limits are 0-15 PSI

PLC

- Allen-Bradley CompactLogix, 24 VDC, Ethernet, located in tethered drive enclosure.

HMI

- 7” Panelview Plus 7, 24 VDC, ethernet, mounted in NEMA 4X enclosure on machine frame

- CL.1 DIV.2

External Finish

- External stainless steel surfaces 39 Ra or better

- Carbon steel surfaces powder coated per RAL 9005 satin

Internal Finish

- All internal surfaces stainless steel with 32 Ra finish or better.

The WSB-40 is designed for the maximum extraction of desired molecules and is suitable for mid to large scale production volumes. This machine can handle up to 40 pounds per 10-to-20-minute cycle and boasts 98% removal of the desired molecules

Technical

Specifications

- General

- 1561 RPM

- 900 Gs

- 133 liter volumetric capacity

- 40 lb maximum biomass load

- 7.2 ft 3 flood volume

- -40°F Minimum operating temperature, 104°F Maximum operating temperature. (32°F to 104°F Ambient)

- Curb

- 304L stainless steel construction with internal vacuum/fluid jacket that covers the entire height of the curb

- Vacuum/fluid jacket supplied with (2) 1/2” NPT connections

- 1-1/4” inertia pad curb floor includes a 3” sanitary fitting for effluent outlet

- Jacket pressure limits are 0-15 PSI

- PLC

- Allen-Bradley CompactLogix, 24 VDC, Ethernet, located in tethered drive enclosure.

- HMI

- 7” Panelview Plus 7, 24 VDC, ethernet, mounted in NEMA 4X enclosure on machine frame

- CL.1 DIV.2

- External Finish

- External stainless steel surfaces 39 Ra or better

- Carbon steel surfaces powder coated per RAL 9005 satin

- Internal Finish

- All internal surfaces stainless steel with 32 Ra finish or better.