For the last decade, the extraction industry has debated the merits of Supercritical CO2 versus Ethanol. CO2 held the crown for “purity” in the early medical market, while ethanol was the workhorse for bulk distillate.

However, as we head toward 2026, a decisive shift is occurring in the industrial landscape. Mid-to-large scale processors are increasingly retiring or repurposing their CO2 systems in favor of Cryogenic Ethanol Extraction. This isn’t a trend driven by hype; it is a calculation driven by Unit Economics.

In a market where margins are tightening and throughput is king, Cryogenic Ethanol has emerged as the most commercially viable path for mass-scale cannabinoid production. Here is why the industry is making the switch, and how Western States Machine Company (WSMC) is powering this transition.

1. The Death of the “Winterization” Bottleneck

The strongest economic argument for Cryogenic Ethanol is the elimination of post-processing steps.

- The Old Way (CO2 or Warm Ethanol): Traditional methods are non-selective regarding plant fats. They extract cannabinoids, but they also pull waxes, lipids, and chlorophyll. To remove these, the crude oil must undergo winterization: dissolving it in ethanol, freezing it for 24-48 hours, and filtering it. This creates a massive bottleneck and requires acres of freezer space.

- The Cryogenic Way: By chilling the solvent to -40°C (-40°F), ethanol becomes highly selective. Physics dictates that plant waxes are insoluble at these temperatures. The solvent grabs the cannabinoids and terpenes but leaves the fats and chlorophyll behind in the biomass.

The Result: You produce “Winterized Crude” directly out of the extractor. You eliminate 24+ hours of processing time, reduce labor costs, and slash your energy bill by removing the need for winterization freezers.

2. Scalability: The “Volume per Hour” Equation

CO2 extraction is excellent for specific high-value niche products, but it is physically limited by cycle times. Pressurizing and depressurizing vessels takes time.

Cryogenic Ethanol Centrifugation is a low-pressure, high-speed mechanical process.

- Throughput: A properly sized centrifuge system can process hundreds of pounds of biomass per hour, far outstripping the capacity of similarly priced CO2 systems.

- Batch Efficiency: With cycle times as low as 10-20 minutes per batch in a Western States WSB-40, operators can turn over thousands of pounds of biomass in a single shift.

For operators looking to produce Full Spectrum Oil, Distillate, or Isolate at a cost-competitive price point, Cryogenic Ethanol offers the lowest Cost Per Gram of processing.

3. The Hidden Cost of Solvent Loss

Switching to ethanol brings one major operational risk: Solvent Loss. Ethanol is an expensive consumable. If your separation equipment leaves 10% or 15% of your solvent soaked into the spent biomass, your operating expenses (OpEx) will destroy your margins.

This is where the centrifuge becomes the most critical piece of equipment on the floor.

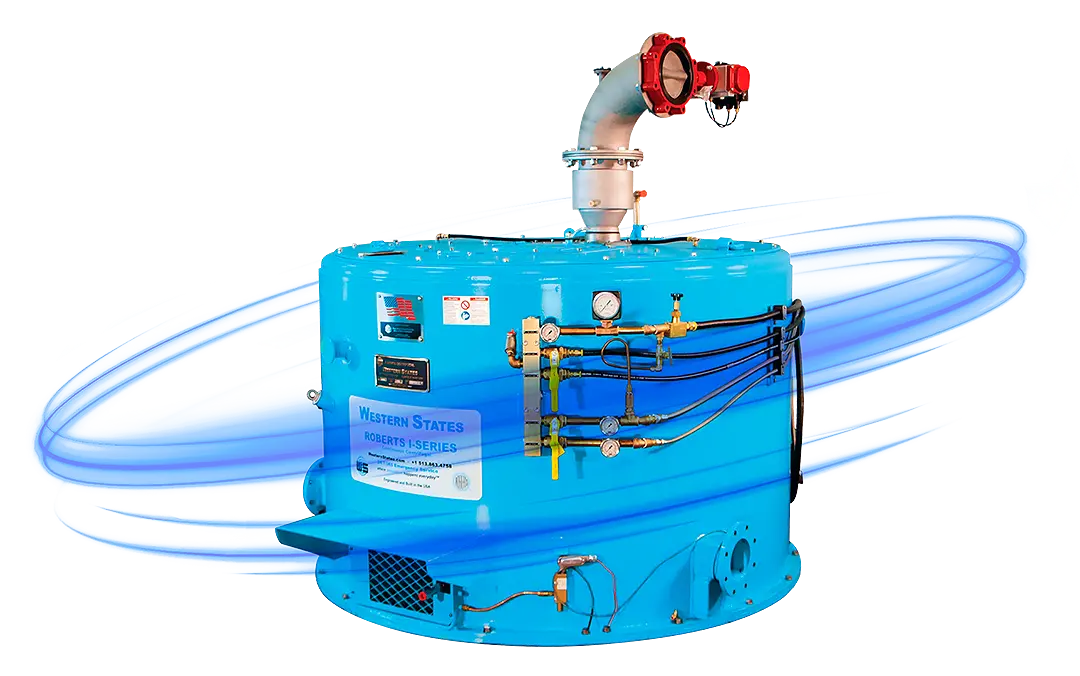

The Western States Advantage: 900 Gs of Recovery

Many “ethanol extractors” are modified laundry spinners that struggle to reach high speeds. Western States engineers centrifuges that generate up to 900 Gs of separation force.

- Maximum Recovery: We drive the solvent out of the biomass, achieving recovery rates of 97% or higher.

- Dryer Biomass: The spent material comes out dryer, which means you are sending less expensive ethanol to the waste disposal or recovery oven.

- Profit Retention: Every gallon of solvent recovered is money staying in your business.

4. Built for the Cold Chain

Running a facility at -40°C is brutal on equipment. Standard seals crack, standard motors fail, and mild steel becomes brittle.

Western States’ WSB Series (WSB-40 and WSB-15) is engineered specifically for the deep freeze:

- Sanitary Design: Constructed with 316L Stainless Steel, ensuring GMP compliance and corrosion resistance.

- Thermal Stability: Our machines are rated for operating temperatures from -40°F to 140°F, allowing you to maintain the cold chain integrity from extraction through separation.

- Safety First: Ethanol is a Class 1 flammable solvent. Our systems come with Class 1, Division 2 (C1D2) explosion-proof motors and controls as standard, protecting your facility and your personnel.

Conclusion: Future-Proof Your Facility

The shift to Cryogenic Ethanol is about maturing from “craft” to “industrial” efficiency. It allows you to skip steps, scale up, and lower your bottom-line costs. But this process relies entirely on the reliability of your separation technology.

Don’t risk your production line on disposable equipment. Invest in the centrifuge manufacturer that has been defining industrial separation since 1917.

Ready to scale? Discover the WSB Series at www.westernstates.com