In the sophisticated and competitive cannabis and hemp extraction market, the quality of the final product is paramount. Processors are in a constant pursuit of methods that yield a pure, potent, and aromatic extract that captures the full profile of the plant. The most valuable compounds—cannabinoids like CBD and THC, and the aromatic terpenes that define a strain’s unique character—are also incredibly delicate. Traditional extraction methods that involve heat can degrade these volatile compounds, diminishing the extract’s quality, therapeutic potential, and market value.

This is where the science of cold comes in. Low-temperature, or cryogenic, ethanol extraction has emerged as the gold standard for producers who refuse to compromise on quality. By leveraging precise temperature control, this method selectively targets the most desirable components of the biomass while leaving unwanted materials behind. The result is a cleaner, more potent, and full-spectrum extract that requires less post-processing and commands a higher price. This article explores the science behind why low-temperature ethanol extraction is the superior method for preserving the valuable profile of cannabinoids and terpenes.

The Challenge: Why Heat is the Enemy of High-Quality Extracts

To understand the benefits of cold extraction, one must first appreciate the fragile nature of the target compounds.

- Terpenes: These are highly volatile organic compounds responsible for the distinct aroma and flavor profiles of different cannabis strains, from the citrus notes of limonene to the pine scent of pinene. They are not only crucial for the sensory experience but are also believed to contribute to the therapeutic “entourage effect.” However, their volatility means they are the first compounds to evaporate or degrade when exposed to heat.

- Cannabinoids: While more stable than terpenes, cannabinoids can also be altered by excessive heat. The extraction process aims to capture valuable acidic cannabinoids like THCA and CBDA, which can be decarboxylated (activated) in a controlled manner later. Uncontrolled heat during the initial extraction can lead to inconsistent decarboxylation and potential degradation of the cannabinoid profile.

Warm extraction methods inevitably co-extract undesirable compounds like chlorophyll, waxes, and lipids from the plant material. While these are natural components, their presence in the final extract results in a darker color, a harsher taste, and requires extensive downstream processing—such as winterization—to remove, adding time, labor, and cost to the operation.

The Solution: Cryogenic Ethanol Extraction Explained

Low-temperature ethanol extraction is a process that uses ethanol chilled to cryogenic temperatures, typically between −40°C and −80°C, to wash the cannabinoids and terpenes from the hemp or cannabis biomass.

The principle is elegantly simple: at these frigid temperatures, ethanol’s properties as a solvent become highly selective. It effectively dissolves cannabinoids and terpenes but leaves the undesirable, less-soluble compounds like waxes, fats, and chlorophyll frozen solid within the plant material. This selective process is the key to producing a cleaner, purer initial extract.

Studies have shown that extraction at −40°C is particularly effective, leading to a higher concentration of terpenes and a slight increase in cannabinoid concentration compared to extractions at warmer temperatures. This precision allows extractors to capture a profile that is much more representative of the living plant.

The Tangible Benefits of Low-Temperature Extraction

Adopting a cryogenic extraction process provides several clear, quantifiable advantages that directly impact both product quality and operational profitability.

1. Maximum Terpene and Cannabinoid Preservation

By keeping the entire process at sub-zero temperatures, the volatile terpenes are protected from evaporation, ensuring the final product retains its intended aroma and flavor profile. Research indicates that terpene content can be over 50% lower when extracting at

−20°C compared to −40°C, highlighting the critical importance of precise temperature control. This preservation results in a truly full-spectrum or broad-spectrum extract that delivers a superior end-user experience.

2. Enhanced Purity and Reduced Post-Processing

Because cryogenic ethanol leaves behind waxes and chlorophyll, the resulting crude oil is significantly purer from the very first step. This high level of purity often eliminates the need for the lengthy and costly step of winterization, where the extract is mixed with ethanol and frozen to precipitate out these same waxes. By avoiding this step, processors can dramatically shorten their production timeline, reduce solvent waste, and lower labor costs.

3. Superior Operational Efficiency

A streamlined process with fewer steps means higher throughput and a better bottom line. By producing a cleaner extract from the start, low-temperature extraction reduces the time and resources spent on filtration and purification. This efficiency, combined with the higher value of the premium-quality final product, delivers a clear and compelling return on investment.

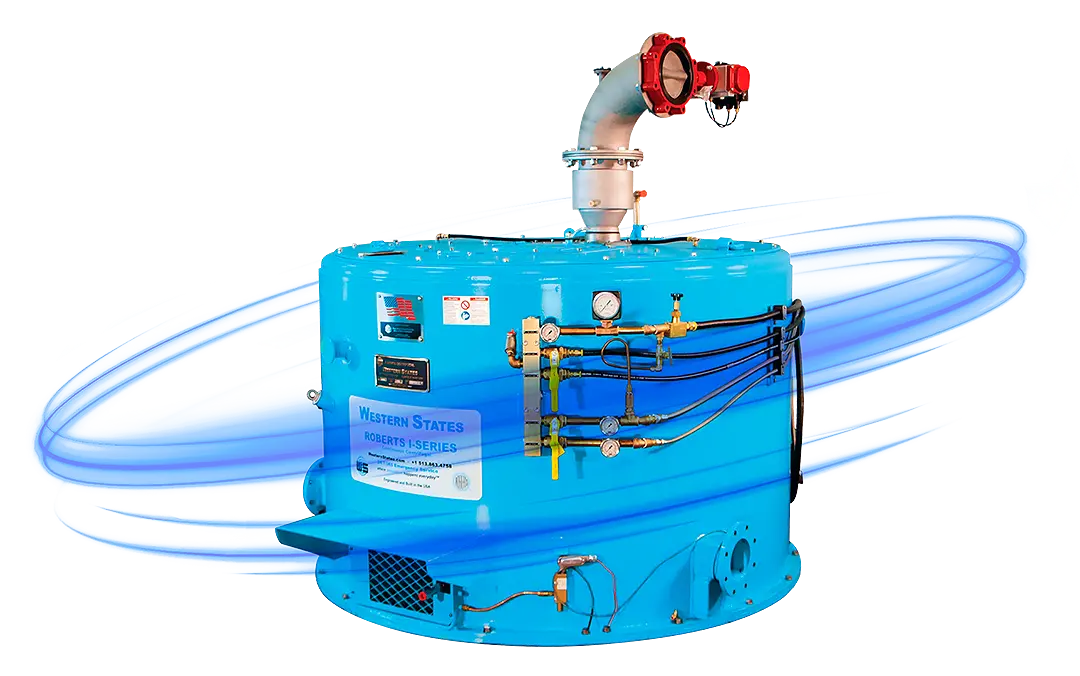

The Critical Role of Equipment: The Centrifuge Advantage

A successful low-temperature extraction strategy is not just about the method; it is about the precision and reliability of the equipment used to execute it. A high-performance botanical centrifuge is the heart of this process, and it must be specifically engineered for the demands of cryogenic operation.

Key features to look for in a botanical centrifuge include:

- Precise Temperature Control: The ability to maintain consistent, ultra-low temperatures is non-negotiable. Jacketed centrifuge systems are essential for ensuring the ethanol and biomass remain at the target cryogenic temperature throughout the wash and spin cycles.

- Safety and Compliance: Working with cold ethanol requires adherence to strict safety protocols. Centrifuges must be equipped with explosion-proof motors and controls (such as Class 1, Division 2 ratings) to ensure safe operation. For products intended for human consumption, construction that adheres to Good Manufacturing Practice (GMP) standards is also critical for ensuring purity and preventing contamination.

- Efficiency and Solvent Recovery: A powerful centrifuge uses high G-forces to spin the solvent from the biomass with maximum efficiency. This ensures that a high percentage of the valuable cannabinoid- and terpene-rich ethanol is recovered, minimizing waste and maximizing yield.

Conclusion: Elevate Your Extraction with the Cold Standard

For cannabis and hemp processors aiming to produce the highest quality extracts, the science is clear. Low-temperature ethanol extraction is the definitive method for preserving the delicate and valuable profiles of cannabinoids and terpenes. By preventing the degradation of these compounds and avoiding the co-extraction of undesirable materials, this technique yields a purer, more potent, and more aromatic product while simultaneously streamlining production and reducing costs.

Achieving these results, however, requires more than just cold ethanol; it requires robust, reliable, and precise equipment. Western States’ botanical centrifuges are engineered in the USA specifically for this demanding application. With advanced temperature control, GMP-ready and C1D2-compliant designs, and a legacy of legendary dependability, our systems provide the foundation you need to optimize your extraction process.

Ready to unlock the full potential of your biomass? Contact a Western States engineer today to discuss how our botanical centrifuges can elevate your extraction process.