In the rapidly maturing cannabis and hemp markets of 2025, the conversation has shifted. While high THC potency once dominated the leaderboard, the sophisticated market—driven by medical efficacy and connoisseur demand—now prioritizes the “Entourage Effect.” This synergy relies not just on cannabinoids, but critically on terpenes, the volatile organic compounds responsible for aroma, flavor, and therapeutic modulation.

For extraction facility operators and process engineers, this shift presents a technical paradox: How do you maximize extraction efficiency without destroying the very volatile compounds that create premium market value?

The answer lies in the physics of temperature and the engineering of separation. It lies in Cryogenic Ethanol Centrifugation.

The Thermodynamics of Loss: Why Terpenes Disappear

Terpenes are notoriously fragile. Monoterpenes like Myrcene and Pinene are highly volatile, with high vapor pressures that make them susceptible to degradation and evaporation even at room temperatures.

- Alpha-Pinene begins to volatilize significantly at temperatures often reached during standard processing steps.

- Limonene and Linalool, critical for the “sativa-like” effects demanded by consumers, are easily lost in heat-intensive recovery processes.

Traditional extraction methods at ambient temperatures often extract unwanted chlorophyll, waxes, and lipids along with the cannabinoids. Removing these impurities requires aggressive post-processing steps like winterization (freezing and filtering) and additional distillation. Every extra step is a “thermal event” where terpenes are lost to heat or evaporation.

The Cryogenic Advantage: Extraction at -40°C

Cryogenic ethanol extraction fundamentally changes the solubility profile of the biomass. By chilling the solvent and the process environment to -40°C (-40°F), we alter the physics of extraction:

- Selective Solubility: At these ultra-low temperatures, ethanol becomes highly selective. It readily dissolves cannabinoids and terpenes but leaves behind water-soluble chlorophyll and heavy plant waxes (lipids).

- In-Line Winterization: Because waxes are insoluble at -40°C, they never enter the oil. This eliminates the need for separate, time-consuming winterization steps, reducing the thermal history of the oil and preserving the delicate terpene profile.

- Volatility Arrest: The low temperature dramatically reduces the vapor pressure of volatile terpenes, “locking” them into the liquid phase rather than allowing them to off-gas into the facility air.

Research indicates that terpene retention can be significantly higher when extracting at -40°C compared to -20°C, preserving the full-spectrum nature of the plant.

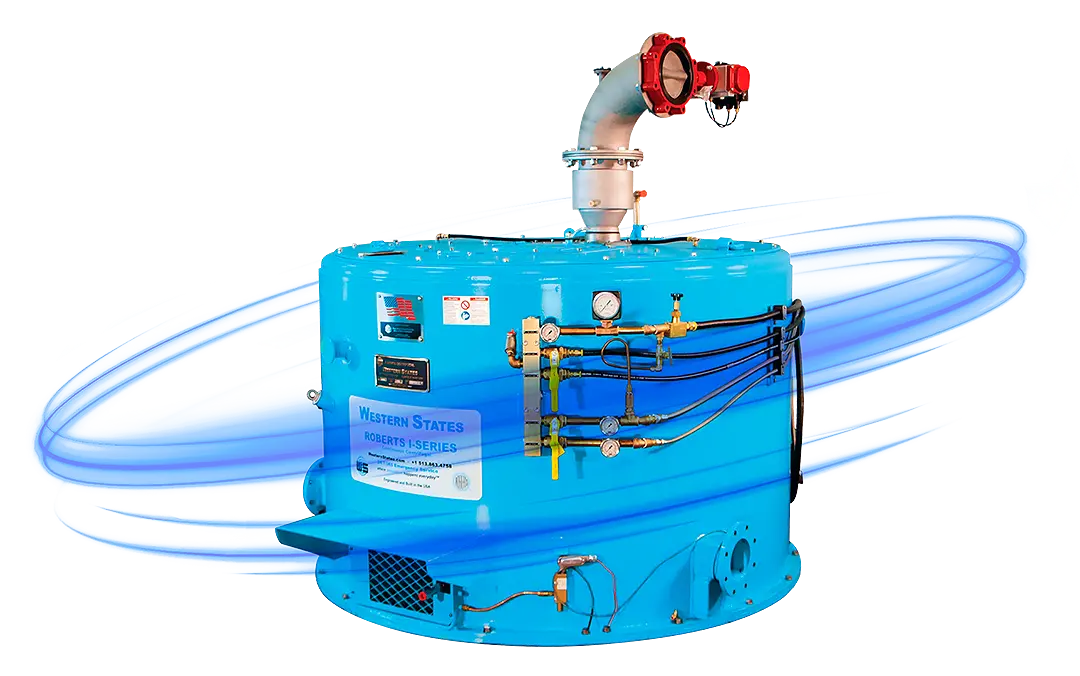

The Engine of Efficiency: The WSB Series Centrifuge

Temperature control is only half the equation. You also need mechanical force to recover that cold, rich solvent from the biomass. This is where Western States Machine Company (WSMC) applies over 100 years of separation expertise.

Our WSB-40 and WSB-15 botanical centrifuges are not adapted laundry machines; they are purpose-built sanitary separation vessels designed for the rigors of cryogenic operation.

Key Technical Advantages for Processors:

- High G-Force Extraction: The WSB-40 generates up to 900 Gs of separation force.1 This ensures maximum solvent recovery from the biomass. Leaving expensive, terpene-rich ethanol soaked in spent biomass is a direct hit to your margins. Our high G-force drives operational efficiency by recovering that value.

- Cryogenic Rating: Unlike standard centrifuges that may suffer from seal embrittlement or metal fatigue at low temperatures, the WSB series is rated for operation from -40°F to 104°F (-40°C to 40°C). Our materials of construction (316L Sanitary Stainless Steel) and sealing technologies are engineered to maintain integrity in deep-freeze environments.2

- Sanitary Design & CIP: In a GMP environment, cross-contamination is a liability. The WSB series features smooth, crevice-free surfaces and integrated Clean-In-Place (CIP) nozzles, allowing for rapid changeovers between strains without risking the integrity of your single-source terpene profiles.1

The Economic Case: ROI Beyond the Machine

Adopting Western States’ cryogenic centrifuge technology is not just an operational decision; it is a financial strategy.

- Premium Pricing: Full-spectrum oils with high terpene content command a premium in the wholesale market over generic distillate. Preserving the native terpene profile allows you to sell “Sauce,” “Live Resin” type products, or high-grade vape oils without adding artificial flavors.

- OpEx Reduction: By eliminating the standalone winterization step (which often requires 24-48 hours in freezers), you reduce electricity costs, floor space requirements, and labor. You go from Biomass to Crude Oil faster.

- “Never Obsolete” Durability: In an industry plagued by “disposable” equipment from overseas, Western States offers a 100-year legacy of durability. We have machines installed in the 1950s that are still running today.3 Buying a WSB centrifuge is a capital expenditure that serves your facility for decades, not months.

Conclusion: Partnering for Purity

The future of botanical extraction belongs to those who can produce the highest quality product at the lowest operating cost. Cryogenic centrifugation with Western States technology allows you to achieve both. You retain the soul of the plant—the terpenes—while deploying a rugged, American-made mechanical solution that guarantees uptime.

Don’t let your profits evaporate.

Contact Western States Machine Company today to audit your current extraction efficiency and discover how the WSB Series can revolutionize your product quality.

(https://www.westernstates.com/high-performance-botanical-centrifuges-for-botanical-extraction/)