Introduction: The Imperative of Scaling in Botanical Extraction

Every successful botanical extractor faces a fundamental challenge: the chasm that separates a promising lab-scale result from a full-scale production operation that is profitable, consistent, and sustainable. Overcoming this hurdle is not just a step in growth; it is the determining factor for long-term success in the competitive cannabinoid market.

Improper scaling leads to a series of predictable and costly problems. Product quality becomes inconsistent, yields that seemed promising in the lab plummet in production, handling large volumes of solvents introduces unforeseen safety risks, and the crippling cost of production downtime can erode profit margins to the point of non-existence. These are not mere setbacks but existential threats to the business.

However, successful and predictable scaling is not an art, but a science. It is a methodical process rooted in a deep understanding of process parameters, a strategic approach to regulatory compliance, and, critically, the selection of robust equipment specifically designed to support the entire growth journey.

This guide offers a clear roadmap for navigating the complexity of scaling. It will detail the crucial phases, from establishing a repeatable process in the research and development (R&D) phase to selecting and implementing full-production machinery. On this journey, Western States is presented as an experienced partner providing not just equipment, but a complete and proven pathway to scale—a necessity for building brand authority in a digital landscape where competitors already offer deep technical content.1

Section 1: The R&D Foundation: Forging a Scalable Standard Operating Procedure (SOP)

The primary goal of the R&D phase is not simply to prove that an extraction concept works, but to define a process that is fundamentally repeatable and scalable. Every decision made in the lab lays the groundwork for success or failure on the production floor. It is at this stage that the critical parameters governing quality and efficiency at any scale must be precisely established.

Key Parameters to Establish

- Solvent Selection and Ratio: The choice of solvent, such as cold ethanol, has profound implications for the final extract profile. It is vital to define a precise solvent-to-biomass ratio that can be consistently maintained as volumes increase. A ratio that works for 100 grams must be accurately replicable for 100 kilograms to ensure product consistency.

- Temperature Control: Temperature is a master variable that directly influences cannabinoid and terpene profiles, as well as the extraction of unwanted compounds like chlorophyll and lipids. Precise and documented temperature control is essential. The equipment used in R&D must be capable of maintaining and recording temperatures accurately, as this capability will be a non-negotiable requirement in large-scale production equipment.

- Residence Time and Agitation: The optimal time the biomass should be in contact with the solvent must be meticulously determined. Too short a time leaves valuable cannabinoids behind; too long, and undesirable compounds are extracted that complicate later purification. Similarly, the agitation method must be sufficient to ensure complete extraction without being so aggressive that it degrades the biomass and releases contaminants.

The Right Tool for the Job: The WSB-MicroPro

To establish these parameters with confidence, the right instrument is needed. The WSB-MicroPro centrifuge is designed precisely for this purpose. It is not simply a small centrifuge; it is a data-generation machine designed for the R&D environment. Its value lies in its ability to efficiently run multiple small-batch trials, allowing process scientists to quickly and accurately fine-tune solvent, temperature, and time variables.1

With its compact size, ideal for laboratories, the WSB-MicroPro provides tangible, reliable data that directly informs the next stage of scaling. This data-driven approach reduces guesswork and prevents costly errors in the pilot and production phases, a problem-solving approach similar to that employed by industry leaders like Alfa Laval to build trust with their customers.1

The true output of the R&D phase is not just a vial of extract; it is a validated dataset and a robust Standard Operating Procedure (SOP). This dataset is the most valuable asset to emerge from the lab. Its function extends beyond scientific validation; it becomes a financial asset. It demonstrates that the process is viable, allows for accurate yield projections, and forms the basis of the business case to justify investment in larger pilot and production equipment. Therefore, the investment in a high-quality R&D centrifuge like the WSB-MicroPro should not be seen as a lab expense, but as the first and most critical investment in the future success of the production facility.

Section 2: The Critical Scaling Bridge: From Grams to Kilograms

The transition from the controlled environment of the lab to a pilot or production scale presents complex, non-linear challenges. Problems that are insignificant at a small scale can become insurmountable obstacles when handling kilograms of biomass and hundreds of liters of solvent. Addressing these challenges requires an understanding of physics, chemistry, and process engineering on an industrial scale.

Subsection 2.1: The Battle for Consistency: Preserving Your Cannabinoid Profile

A process that produces a perfect extract with 100 grams of biomass can fail spectacularly with 100 kilograms. This is due to two main physical phenomena: thermal management and mass transfer limitations. Processing larger volumes generates more heat, which can degrade sensitive cannabinoids and terpenes. Furthermore, ensuring that the solvent uniformly penetrates every particle of a large mass of biomass is a significant challenge. The engineering of an industrial centrifuge is designed to solve precisely these problems. Features like jacketed vessels for precise temperature control and baskets designed for uniform flow distribution are direct solutions to these scaling physics challenges.1

Subsection 2.2: The Economics of Extraction: Optimizing Yield, Purity, and Throughput

In a production environment, there is a delicate balance between processing speed (throughput) and the quality of the final product. Processing too quickly can decrease yield or carry over fats, waxes, and other unwanted compounds that will require costly post-processing steps. The primary tool for optimizing this balance is precise control of G-force (centrifugal force) and variable speed. An industrial centrifuge allows the operator to adjust these parameters to find the sweet spot where throughput is maximized without sacrificing the purity of the extract—an essential control for the economic viability of the operation.

Subsection 2.3: Solvent Management at Scale: Safety and Financial Imperatives

Handling thousands of liters of flammable solvents like ethanol introduces a whole new level of risk. Worker safety and facility integrity become the top priority. Extraction systems at scale must be contained, closed-loop systems to manage vapors and prevent leaks. Additionally, from a financial perspective, efficient solvent recovery is crucial. Losing even a small percentage of solvent in each cycle can translate into enormous operating costs over time. Robust industrial centrifuges are designed for superior containment and solvent recovery of up to 99%+, addressing both the safety and financial imperatives. This focus on operation in demanding environments is a tactic used by competitors like Flottweg to demonstrate their expertise in regulated applications, and it positions Western States’ equipment as inherently safer and better suited for these demands.1

Subsection 2.4: The GMP Challenge: Designing for Compliance from Day One

To produce high-value products intended for human consumption, compliance with Good Manufacturing Practices (GMP) is non-negotiable. Designing a facility and selecting equipment with GMP in mind from the outset is far more efficient and cost-effective than trying to retrofit a system later. “GMP-ready design” is not just a marketing term; it refers to tangible features that are auditable and meet regulatory standards. These include the use of 316L stainless steel for all product-contact surfaces, smooth, polished sanitary welds that prevent bacterial buildup, Clean-in-Place (CIP) capabilities, and full material traceability. Selecting equipment that already incorporates these design principles greatly simplifies the path to GMP certification.1

Section 3: The Industrial Centrifuge: Your Engine for Scalable Separation

The reason the industrial centrifuge has become the undisputed standard for botanical extraction at scale is simple: it offers unparalleled efficiency, speed, and consistency for liquid-solid separation. Its superiority is not marginal; it represents a quantum leap compared to other methods.

The Mechanics of Superiority

The operating principle of a centrifuge is the application of immense G-force (thousands of times the force of gravity) to rapidly separate the cannabinoid-rich tincture (the liquid) from the spent biomass (the solid). When contrasting this method with common lab-scale or less efficient alternatives, such as Büchner funnels or simple filter presses, the advantages become clear. A separation cycle in a centrifuge can be completed in minutes, whereas other methods can take hours. Solvent recovery can exceed 99%, minimizing losses. And most importantly, the process is highly repeatable, producing a consistent quality extract batch after batch.

Key Benefits in a Production Context

- Automation and Labor Savings: Modern industrial centrifuges feature automated cycles controlled by a PLC (Programmable Logic Controller). This reduces the need for manual operator intervention, which translates to lower labor costs and a drastic reduction in the risk of human error.

- Process Containment: Operation in a closed-loop system is fundamental for safety in handling solvents and for preventing product contamination from the environment. A centrifuge is, by design, a contained system.

- Data Logging and Repeatability: Modern PLC controls allow for precise management of “recipes” (pre-defined process parameters) and data logging for each batch. This documentation capability is a cornerstone of GMP compliance, providing an auditable record that each batch was processed according to specifications.

A modern industrial centrifuge is much more than a simple separation device; it functions as a Critical Control Point (CCP) for the entire downstream process. The quality of its output—the raw tincture—directly dictates the efficiency, cost, and workload of every subsequent step in the production line.

The reasoning is clear: the centrifuge separates the crude oil from the biomass. The effectiveness of this separation, i.e., the amount of residual solvent and fine particles left in the oil, directly impacts the load on subsequent equipment. A high-performance centrifuge that produces a cleaner, drier crude oil significantly reduces the burden on winterization and filtration systems. It makes solvent recovery faster and more energy-efficient. Ultimately, it leads to a higher purity final product with fewer processing steps. Therefore, investing in a high-performance centrifuge is not just an investment in separation; it is an investment in optimizing the entire downstream workflow. It is a leverage point where a small improvement in centrifuge performance has a cascading positive financial effect, reducing the total cost per gram of final distillate.

Section 4: The Western States Pathway: A Phased Approach to Equipment Selection

Scaling is not a single event, but a journey. Western States understands this and has designed its line of botanical centrifuges as a complete, integrated solution that grows with the customer’s business. This phased approach directly maps the scaling journey to the product line, turning the sales proposition into a logical and helpful guide.

Subsection 4.1: Pilot Scale and Process Validation (The WSB-15)

The WSB-15 acts as the essential bridge between R&D and full-scale production. It is designed for producers who are ready to manufacture their first small commercial batches, validate their SOP at a larger scale, and generate product for market testing. This process validation stage is critical; it proves that the process developed on the WSB-MicroPro holds up at a 10x or 20x scale before committing to a capital investment in a full production machine. It is at this stage that many producers collaborate with equipment partners to arrange trials or short-term rentals, validating their process on production-intent machinery and completely de-risking their final investment—a flexible partnership approach inspired by the strategies of competitors like Flottweg.1

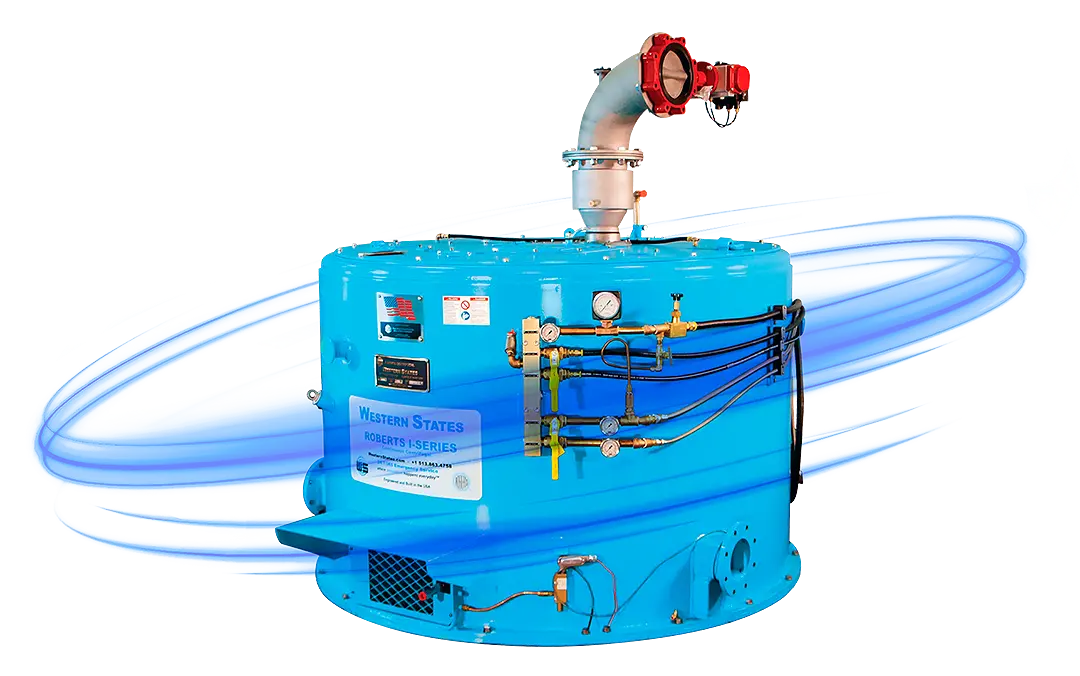

Subsection 4.2: The Full-Scale Production Powerhouse (The WSB-40)

For operations requiring high throughput and 24/7 operation, the WSB-40 is the definitive solution. It is designed to be the workhorse of a large-scale production facility. Its features are focused on what matters most at this scale: high biomass capacity per batch, fast cycle times to maximize throughput, robust automation via PLC controls, and an industrial design built for continuous, reliable operation.1

Western States Scalability Matrix: Your Decision Guide

To clearly visualize this growth pathway, the following table serves as a decision-making tool. It summarizes the entire product line and allows a potential customer to immediately identify which machine fits their current and future needs, transforming a list of features into a strategic guide.

| Parameter | WSB-MicroPro | WSB-15 | WSB-40 |

| Ideal Use Case | R&D, Data Generation, SOP Optimization | Pilot Scale, Process Validation, Small Commercial Batches | Full-Scale Production, 24/7 Operation, High Throughput |

| Biomass Capacity (lbs per batch) | 2-4 | 15-20 | 40-50 |

| Max G-Force | 1,000 xg | 1,000 xg | 1,000 xg |

| Operating Temp. Range | −40∘C to +20∘C | −40∘C to +20∘C | −40∘C to +20∘C |

| Control System | Manual / Basic Digital | Semi-Automated | Fully Automated PLC |

| GMP-Ready Features | Lab Grade | GMP-Ready | Full GMP Documentation |

| Safety Features | Basic Containment | Industrial Safety Interlocks | Class I, Div 1 Options Available |

| Typical Throughput | Grams/hour | Kilograms/hour | Tons/day |

Section 5: Beyond the Spec Sheet: The ROI of “Legendary Dependability”

In a market filled with equipment options, technical specifications are only part of the equation. The true long-term value of a capital investment lies in its reliability and Total Cost of Ownership (TCO). This is where the core differentiator of the Western States brand, its “Legendary Dependability,” becomes a decisive factor.1

The True Cost of Downtime

In a full-production facility, downtime is not an inconvenience; it is a financial catastrophe. Every hour a machine is down translates into lost revenue, missed delivery deadlines, idle staff, and potential damage to the brand’s reputation. The cost of downtime often far exceeds any initial savings from purchasing cheaper, less reliable equipment.

The Western States value proposition is the antidote to this risk. The fact that the company has machines built in the 1950s that are still in operation worldwide is a powerful testament to the build quality and robust engineering.1 This longevity must be reinterpreted for the modern extractor. Reliability is not about the machine lasting 50 years; it is about the machine running without failure for the next 50 production shifts. In an emerging and volatile industry where many startups fail, building an operation on an industrially proven, robust platform is a key strategic advantage. It is about operational continuity. The 5-year warranty on the centrifuge basket is not just a feature; it is a financial guarantee of uptime and peace of mind.1

The Partnership Pillar: Superior Customer Service

Equipment reliability is complemented by the second pillar of the Western States value proposition: “Superior Customer Service”.1 This translates into tangible, practical support that extends beyond the initial sale. It means having access to expert technicians who understand both the machine and the extraction process. It means on-site training to ensure the customer’s team can operate the machinery safely and efficiently. And it means having spare parts readily available to minimize any potential downtime. The purchase of a Western States centrifuge is not a transaction; it is the beginning of a long-term partnership dedicated to the customer’s success.

Conclusion: Scale with Confidence, Build for the Future

The path from a lab concept to a market-leading product is complex, but it does not have to be uncertain. The key to success lies in a methodical, strategic approach to scaling.

The key takeaways from this guide can be summarized in four fundamental principles:

- Scaling is a deliberate, science-based process that begins with creating a robust, repeatable SOP in the R&D phase.

- Industrial centrifuges are the proven, industry-standard technology for efficient, safe, and compliant separation at a production scale.

- Western States offers a clear, phased equipment pathway that grows with your business, from the WSB-MicroPro for R&D to the WSB-40 for full-scale production.

- True long-term profitability is built on reliable equipment that minimizes downtime and reduces the total cost of ownership—a principle embodied in the “Legendary Dependability” of Western States.

Ultimately, Western States offers more than just machines; it offers a complete, proven roadmap from the lab to market leadership, backed by over a century of engineering excellence.