In the high-stakes environment of hemp and botanical extract production, we face a dual challenge: the need for aggressive solvents to ensure efficient mass transfer and the strict obligation to deliver a product free of elemental impurities. As production managers, our reputation and brand viability depend on ensuring that the equipment does not negatively interact with the process. Stainless steel is not merely an aesthetic choice; it is an essential chemical and biological barrier. The difference between operational success and a batch rejected for heavy metals often lies in the metallurgy of the contact surfaces.

Technical Analysis: The Science Behind Grades 304L and 316L

Stainless steel is an alloy of iron and chromium that forms a passive layer of chromium oxide on its surface, which automatically regenerates in the presence of oxygen. However, not all stainless steels are equal when it comes to extraction.

SS304L: The Sanitary Workhorse

Grade 304L (the “L” stands for low carbon, maximum 0.03%) is the food industry standard. With approximately 18% chromium and 8% nickel, it offers excellent corrosion resistance in controlled environments. It is ideal for structural components and contact surfaces with less aggressive solvents or in stable cryogenic conditions where corrosion kinetics are minimal.

SS316L: The Superior Pharmaceutical Grade

For operations facing higher chemical risks, SS316L is the “gold standard”. The critical addition of 2–3% molybdenum provides superior resistance against pitting and crevice corrosion, particularly in the presence of chlorides or solvents that may become acidic over time.

Table 1: Composition and Resistance Comparison

| Element/Property | SS304L | SS316L | Strategic Impact |

| Chromium (Cr) | 17.5 – 19.5% | 16.5 – 18.5% | Baseline oxidation resistance |

| Nickel (Ni) | 8.0 – 10.5% | 10.0 – 13.0% | Structural stability and ductility |

| Molybdenum (Mo) | 0% | 2.0 – 3.0% | Vital for chloride and acid resistance |

| Pitting Resistance | Moderate | Superior | Prevents micro-cavities that harbor biofilms |

The Critical Risk: Heavy Metal Leaching

Hemp and cannabis are hyper-accumulator plants; they naturally absorb heavy metals not just from the soil, but from any surface they contact. Using low-quality metals or carbon steels can lead to the leaching of iron (Fe), nickel (Ni), and chromium (Cr) ions into the extract.

Research indicates that prolonged immersion of stainless steel surfaces without proper finishing in organic solvents can release significant trace metals. In a market where action limits for heavy metals in Certificates of Analysis (COA) are increasingly strict, any cross-contamination from equipment can result in the total loss of production batches.

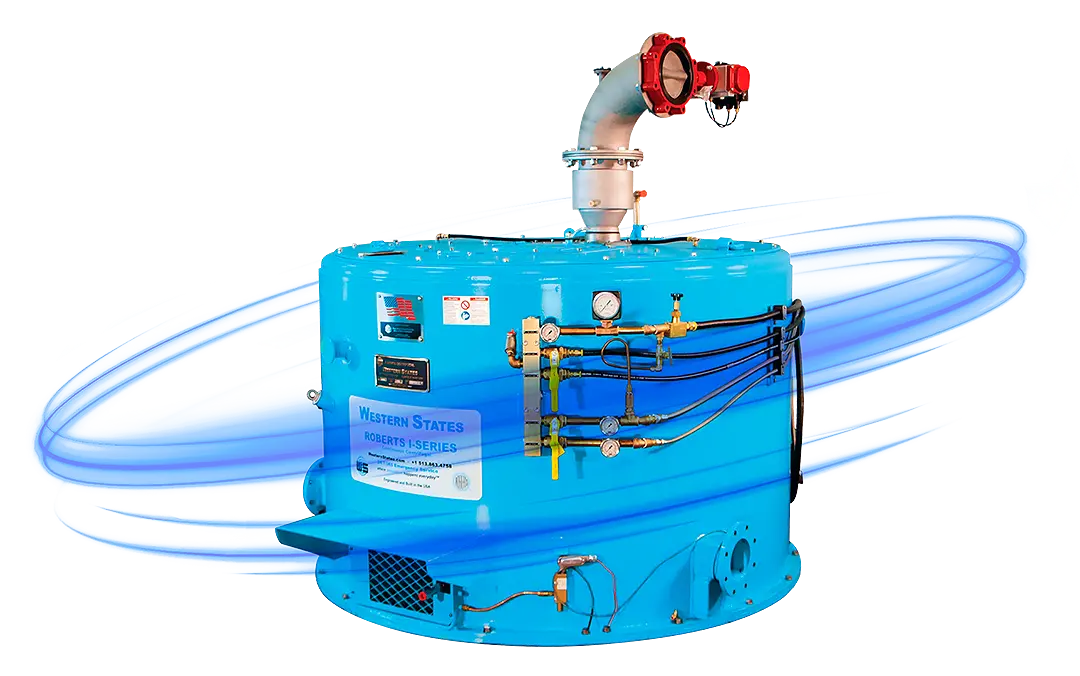

Strategy with Western States: Precision Engineering in Steel

Western States Machine Company designs its WSB botanical centrifuge series by strategically integrating these materials to optimize Return on Investment (ROI) and product safety.

1. Wetted Parts Construction

All surfaces that come into contact with the biomass and solvent in the WSB-MicroPro, WSB-15, and WSB-40 models are manufactured from sanitary SS304L or SS316L stainless steel. This ensures the separation process occurs in an inert environment, protecting terpene and cannabinoid profiles from chemical alteration.

2. Surface Finish: The Ra Factor

Metallurgy is only half the story; surface finish is equally critical. Western States guarantees an internal finish of 32 Ra (Roughness Average) or better on all internal surfaces.

- ASME BPE Hygiene: According to bioprocessing standards, a smooth surface (

) minimizes adhesion sites for microbes and facilitates cleaning.

- Clean-In-Place (CIP): The smoothness of Western States centrifuge surfaces, combined with strategically placed CIP nozzles, ensures that sticky biomass residues do not become embedded, eliminating the risk of cross-contamination between batches.

3. Welding and Durability

Western States’ use of “L” (Low Carbon) variants is vital for structural integrity. During welding, standard steels can suffer from “sensitization,” where chromium is depleted in weld zones, making them vulnerable to corrosion. By utilizing SS304L and SS316L, Western States eliminates this risk, allowing their equipment to maintain “Legendary Dependability” for decades under heavy industrial use.

Frequently Asked Questions (FAQ)

What is the main difference between 304L and 316L stainless steel for extraction?

The primary difference is the addition of 2-3% molybdenum in 316L stainless steel. This element significantly enhances resistance to corrosion, pitting, and stress-corrosion cracking caused by chlorides and harsh chemical cleaning agents.

Why is the “L” suffix (e.g., 316L) important in extraction equipment?

The “L” stands for “Low Carbon” (). Lower carbon content prevents chromium carbide precipitation during welding—a process known as “sensitization”—which otherwise leaves the weld areas vulnerable to rapid corrosion and structural failure.

Can using the wrong grade of steel cause a batch of extract to fail heavy metal testing?

Yes. Since cannabis is a hyper-accumulator, it can leach heavy metals like iron, nickel, and chromium directly from equipment surfaces that are corroded or made of inferior alloys. Using high-grade 316L stainless steel with a proper finish is essential to avoid contaminating your Certificate of Analysis (COA).

What is “Ra 32” finish and why does it matter for sanitation?

Ra stands for Roughness Average. A 32 Ra finish (approximately 0.8 microns) is the sanitary standard for food and pharmaceutical processing. Smoother surfaces prevent “micro-cavities” where bacteria, molds, or sticky resins can hide, ensuring that automated cleaning processes are fully effective.

Does Western States equipment support automated Clean-In-Place (CIP)?

Absolutely. Western States centrifuges are engineered with integrated CIP nozzles that provide 100% spray coverage of internal surfaces, including “blind zones” like the area behind the basket. This automation reduces human error and ensures repeatable sanitation between batches.

Strategic Conclusion for Production Management

Investing in Western States equipment manufactured with SS304L/SS316L is not an additional cost; it is an insurance policy against:

- Lab Test Failures: Prevents contamination from leached heavy metals.

- Downtime: Smooth, chemical-resistant surfaces reduce cleaning and maintenance times.

- Premature Obsolescence: Superior corrosion resistance ensures the equipment passes GMP audits today and ten years from now.

At Western States, material selection is based on a century of technical expertise. By choosing these centrifuges, we are choosing the safest path to a high-purity product and a profitable, scalable operation.