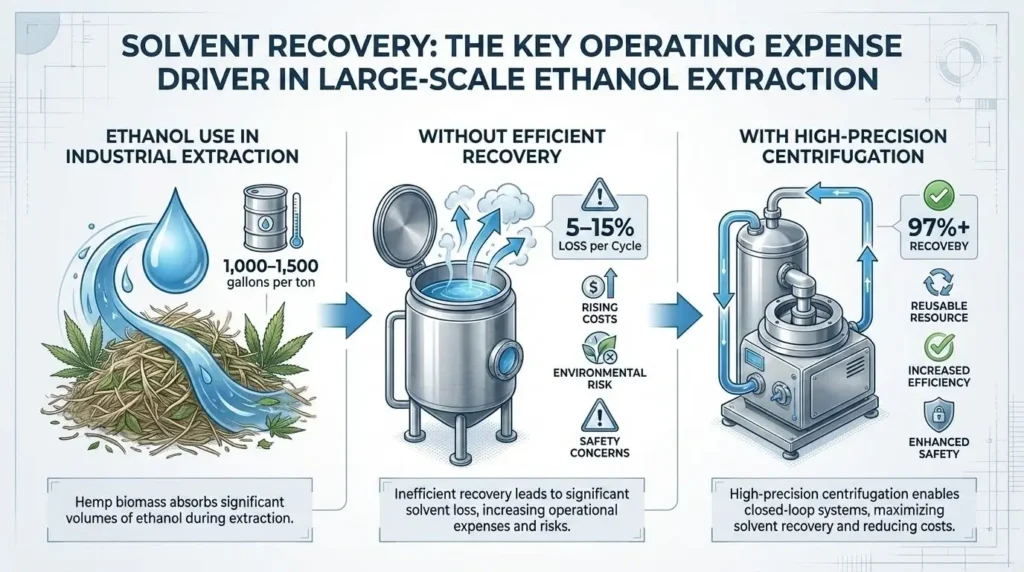

In the complex landscape of industrial hemp production, efficiency is more than just a performance metric; it is the pivot upon which the economic viability of an entire operation turns. As production managers, we face a daily reality where the market demands pharmaceutical-grade purity while simultaneously exerting downward pressure on prices. In this environment, solvent recovery emerges as the most critical variable in the Operating Expense (OpEx) structure. A facility’s ability to recover, purify, and reuse ethanol defines its profit margins and its ability to scale without variable costs eroding profitability. Analysis of industry best practices reveals that mechanical separation technology—specifically high-precision centrifugation—is the deciding factor in achieving recovery rates exceeding 97%, transforming a costly waste stream into a renewable resource.1

Overview: The Imperative of Ethanol Efficiency

Ethanol extraction has established itself as the gold standard for large-scale cannabinoid production due to its versatility, safety, and food-grade status.3 However, ethanol’s competitive advantage is threatened by its physical nature: it is a highly absorbent solvent that tends to remain trapped within the porous matrix of hemp biomass.5 Operational data indicates that a plant processing one ton of biomass per day may require between 1,000 and 1,500 gallons of ethanol to ensure full saturation and efficient mass transfer. Without a robust recovery strategy, solvent replacement costs can become the single largest expenditure after raw material.

The challenge of solvent recovery begins the moment ethanol contacts the plant. Traditionally, the industry has struggled with losses ranging from 5% to 15% of total volume per cycle. These losses are not merely financial; they represent environmental risks and a burden on plant ventilation and safety systems. Adopting centrifugation technologies designed specifically for this purpose—rather than adapting machinery from less demanding industries—allows processors to address the problem at its root: mechanical liquid-solid separation with optimized G-forces.

Table 1: Impact of Recovery Rates on Annual Operating Expenses

| Recovery Rate | Solvent Loss per Batch (Gallons) | Daily Replenishment Cost (USD)* | Impact on Cost-per-Gram |

| 85% | 150 – 225 | $700 – $1,050 | High |

| 92% | 80 – 120 | $375 – $565 | Moderate |

| 97%+ | < 30 – 45 | $140 – $210 | Minimal |

*Based on an average ethanol cost of $4.71 per pound and a 1,000 lbs/day operation.

Detailed Analysis: Separation Science and Thermodynamics

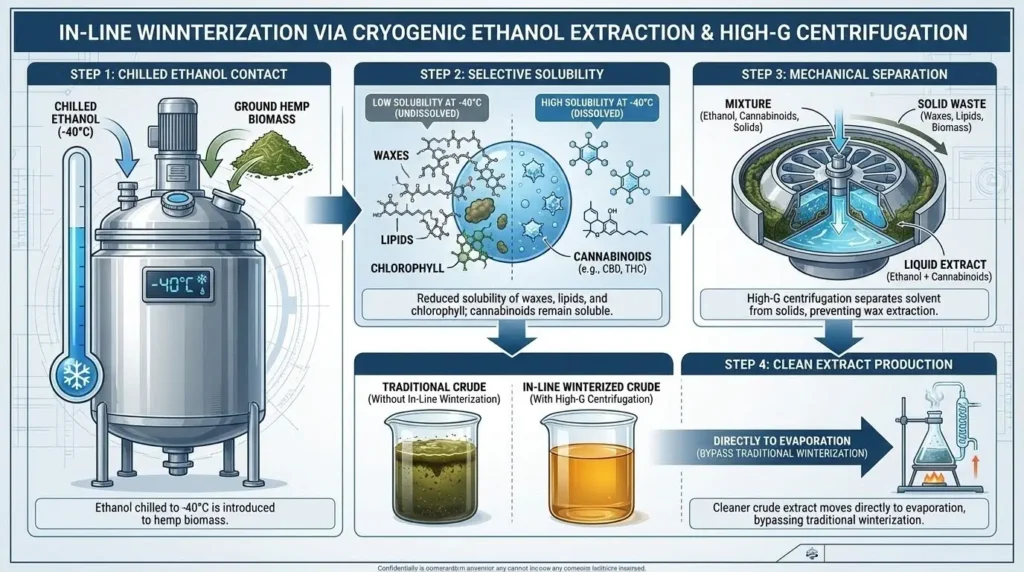

Optimizing solvent recovery requires a fundamental understanding of the interaction between temperature, solubility, and centrifugal force. Cryogenic extraction, operating at temperatures of $-40^{\circ}C$ or lower, is the cornerstone of an efficient process.3 At these extreme sub-zero levels, the solubility of lipids, plant waxes, and chlorophyll drops drastically, while ethanol’s affinity for cannabinoids and terpenes remains high enough to ensure superior yields.3

Synergy Between Cryogenic Temperatures and Selectivity

When ethanol is chilled to cryogenic levels, it behaves as a much more selective solvent. This phenomenon, often called “in-line winterization,” is a critical driver for cost reduction.1 By preventing the extraction of fats and waxes from the start, you eliminate the need for lengthy and expensive post-processing steps where solvent is traditionally lost during cold filtration stages. A process requiring less refinement is, by definition, a process that consumes less solvent and less energy.

Maintaining these temperatures during the centrifugation cycle is where Western States’ engineering excels. Equipment like the WSB-40 is designed with internal vacuum/fluid jackets that envelop the processing zone, ensuring the “thermal gradient” is minimized and selectivity remains constant from the first to the last second of the cycle. This prevents premature solvent evaporation within the machine, which not only improves safety by reducing flammable vapors but also ensures the ethanol is recovered in its liquid phase for immediate collection.4

The Physics of Separation: The Role of Relative Centrifugal Force (RCF)

The efficiency with which solvent is recovered from spent biomass is directly tied to the Relative Centrifugal Force (RCF) the centrifuge can generate. The mathematical relationship governing this process is:

$$RCF = 1.118 \times 10^{-5} \times r \times rpm^2$$

Where $r$ is the rotor radius and $rpm$ is the revolutions per minute. Western States’ botanical centrifuges are calibrated to generate up to 900 Gs of separation force. This magnitude of force is necessary to overcome the capillary forces that keep ethanol trapped in hemp fibers. A marginal increase in G-force can result in a substantial reduction in residual “cake” moisture, translating directly into gallons of ethanol saved per cycle.

Strategy Linked to Western States Equipment

As managers responsible for profitability and operational continuity, the choice of separation equipment should not be based solely on Capital Expenditure (CapEx), but on Total Cost of Ownership and long-term reliability. Western States Machine Company brings a legacy of over a century in centrifugation engineering, having perfected systems in the sugar and pharmaceutical industries where efficiency and purity are non-negotiable.

The WSB Botanical Centrifuge Line

The WSB series from Western States was specifically designed to bridge the gap between craft extraction and industrial pharmaceutical production. These are not adapted machines; they are sanitary separation vessels built from the ground up to operate in extreme cryogenic conditions and C1D2 rated environments.

WSB-40: Power for High-Throughput Production

The WSB-40 represents the capacity standard for medium-to-large processing facilities. With a capacity of up to 40 pounds of dry biomass per cycle, it enables a continuous workflow that minimizes downtime.

| Technical Specification | Value | Impact on Production |

| Maximum G-Force | 900 Gs | Up to 97%+ solvent recovery 6 |

| Biomass Capacity | 40 lbs (18.1 kg) | High processing density per square foot |

| Temperature Range | $-40^{\circ}C$ to $40^{\circ}C$ | Thermal stability for delicate terpene profiles 6 |

| Average Cycle Time | 10 – 20 minutes | Rapid inventory and biomass turnover |

| Material of Construction | 304L/316L Stainless Steel | Corrosion resistance and GMP compliance |

The strategic advantage of the WSB-40 lies in its consistency. In production management, variability is the enemy of profitability. Equipment that guarantees the same recovery rate and purity in every batch allows for more accurate financial planning and reduces the need for additional lab testing to correct crude quality deviations.

WSB-15 and WSB-MicroPro Models

For scaling operations or R&D departments, Western States offers the WSB-15 and WSB-MicroPro. These units maintain the same engineering and material standards as their industrial counterparts, allowing for a frictionless transition from process validation to commercial production. Scaling a process using the same base technology reduces engineering risks and accelerates time-to-market.

Durability: The “100-Year Machine” Concept

A profound differentiator for Western States is the longevity of its machines. In an industry where many competitors offer equipment that becomes obsolete or fails mechanically in less than five years, Western States has centrifuges installed in the 1950s that are still in operational service. For a production manager, this means the equipment ROI spans decades, diluting depreciation costs and providing operational stability that is difficult to match with low-cost “disposable” suppliers.

Operational Practices to Maximize Solvent Recovery

Implementing the right equipment is only half the equation; the other half lies in operational protocols and system parameter optimization. The following critical strategies should be integrated into the Standard Operating Procedures (SOPs) of any facility utilizing Western States technology.

Centrifugation Cycle Optimization

Not all plant materials are the same. Hemp density, grind size, and initial moisture content affect separation dynamics. Utilizing Western States’ advanced PLC controls, operators can adjust acceleration ramps and dwell times at maximum speed to maximize solvent expulsion. An optimized final spin cycle can reduce residual biomass moisture by an additional 2-3%, which in a large-scale operation represents thousands of liters of ethanol recovered annually.1

Clean-In-Place (CIP) System Management

Cross-contamination and resin buildup can degrade mechanical efficiency and product purity. Western States equipment integrates strategically placed CIP nozzles that ensure full coverage of internal surfaces, including blind zones behind the basket.6 Effective cleaning not only ensures quality but also protects seals and bearings from the buildup of sticky resins that could increase friction and energy consumption.12

Inert Atmosphere and Operational Safety

Safety is an intrinsic component of operational efficiency. Processing large volumes of ethanol, even at low temperatures, carries fire and explosion risks. Western States centrifuges are prepared for nitrogen or argon inerting, using oxygen sensors that interlock operation if the internal atmosphere becomes hazardous.4 This level of safety protects both human and physical capital and is a fundamental requirement for obtaining regulatory compliance and favorable insurance policies.4

Reducing Post-Processing Costs

The impact of efficient solvent recovery extends far beyond the centrifuge. By producing a crude extract with minimal lipid and wax load (thanks to Western States’ cryogenic operation), you drastically reduce the workload on downstream evaporation and distillation systems.

Benefits for Falling Film Evaporation

Cleaner crude means that falling film evaporators can operate for longer periods before requiring cleaning shutdowns. Plant waxes tend to foul evaporator tubes, reducing heat transfer efficiency and increasing steam or electricity consumption.14 By removing these waxes in the centrifuge at $-40^{\circ}C$, the thermal efficiency of the solvent recovery evaporation system is maintained, lowering the energy cost per gallon recovered.17

Eliminating Traditional Winterization

Traditional winterization requires mixing extract with ethanol and freezing it for 24-48 hours, followed by slow filtration. This step is a logistical bottleneck and a major source of solvent loss through evaporation and filter retention. The ability of WSB centrifuges to perform “mechanical in-line winterization” allows many applications to skip this step entirely, reducing total OpEx by 15-20% and freeing up valuable floor space.1

Quality, Compliance, and Traceability

In the 2025 global cannabinoid market, traceability is currency. Regulators in Europe and North America increasingly demand proof that equipment used in extract manufacturing meets sanitary design standards and does not introduce contaminants into the final product.19

Sanitary Design and Certified Materials

Western States exclusively uses high-purity stainless steels (304L, 316L, Duplex) and exotic alloys if the process requires.13 All welds are X-ray inspected, and surfaces are mechanically polished to eliminate porosity.13 This level of detail ensures extracts do not contain leached heavy metals or cross-batch contaminants, facilitating compliance with international pharmacopeias.15

Automation and Electronic Records

Integrating industry-compatible control systems allows for the generation of electronic records for every cycle. This data includes temperature profiles, rotation speeds, jacket pressures, and soak times.1 For production management, having this tabulated information is essential for root cause analysis in case of quality deviations and for continuously optimizing process efficiency through historical data analysis.1

ROI Analysis and Total Cost of Ownership

When evaluating a Western States centrifuge, financial management often focuses on the initial sticker price. However, a proper ROI analysis must consider accumulated operational savings over the first 24 months.

The Cost of Inefficiency

Comparing a Western States centrifuge achieving 97% recovery with a low-cost alternative reaching only 90%, the 7% difference in solvent loss is staggering. In an operation using 1,000 gallons daily, that 7% represents 70 gallons of ethanol lost every day. At a conservative cost of $5 per gallon, this adds up to $350 daily—or approximately $126,000 annually in solvent loss alone. In less than two years, the “cheaper” machine will have cost more than the premium Western States investment just in wasted raw materials.

Labor and Energy Savings

The automation and ease of maintenance in Western States equipment reduce operator workload. A machine that does not require constant manual intervention for balancing or cleaning allows staff to focus on higher-value tasks. Furthermore, the mechanical efficiency and reduced friction in Western States systems translate into lower kilowatt consumption per pound of biomass processed, contributing to corporate sustainability goals.1

Conclusion: The Production Manager’s Decision

Ultimately, managing a hemp extraction plant is about mitigating risk and maximizing asset yield. Solvent recovery is not a peripheral aspect; it is the economic heart of the process. By choosing Western States Machine Company, a production manager opts for a solution proven over a century in the most demanding industrial conditions.

The combination of superior G-forces, stable cryogenic operation, sanitary construction, and unmatched technical support makes the WSB series the logical choice for any operation aspiring to excellence. Reducing operating costs is not achieved through equipment shortcuts, but through investment in precision engineering that ensures every drop of solvent is recovered and every gram of hemp potential is extracted. Western States does not just sell machines; it provides the infrastructure necessary for the hemp industry to achieve maturity as a global, profitable, and sustainable manufacturing sector.1

As production leaders, our responsibility is to choose technology partners who share our commitment to quality and efficiency. Western States represents that commitment, offering the “Legendary Dependability” needed to transform operational challenges into sustainable financial victories.

References

- High-Performance Botanical Centrifuges for Botanical Extraction – Western States: https://www.westernstates.com/high-performance-botanical-centrifuges-for-botanical-extraction/

- Western States | Centrifuge Manufacturers in the USA for Chemical & Pharma – Western States: https://www.westernstates.com/

- Cold Ethanol Extraction: Effective Techniques, Benefits & Uses – Root Sciences: https://www.rootsciences.com/blog/exploring-cold-ethanol-extraction-techniques-benefits-and-applications/

- Cost-Effective Ethanol Extraction with Industry-Leading Botanical Centrifuges: https://www.westernstates.com/cost-effective-ethanol-extraction/

- Ethanol Extraction: Explained – extraktLAB: https://extraktlab.com/ethanol-extraction/

- The Cold Standard: Unlocking Superior Terpene Retention with Cryogenic Centrifuge Technology – Western States: https://www.westernstates.com/the-cold-standard-unlocking-superior-terpene-retention-with-cryogenic-centrifuge-technology/

- Cryogenic Ethanol Extraction Guide – The Original Resinator: https://www.theoriginalresinator.com/blog/cryogenic-ethanol-extraction/

- The Cold Standard: How Low-Temperature Ethanol Extraction Preserves Cannabinoids and Terpenes – Western States: https://www.westernstates.com/the-cold-standard-how-low-temperature-ethanol-extraction-preserves-cannabinoids-and-terpenes/

- Extracción criogénica de etanol: etapas, ventajas e inconvenientes – Green Exchange: https://green-exchange.eu/es/blog/extraction-ethanol-cryogenique/

- Top Centrifuge Maintenance Tips for the Oil & Gas Industry – Diamond T Services: https://diamondtservices.com/top-maintenance-tips-for-centrifuges-in-the-oil-and-gas-industry/

- Types of Sugar Centrifuges: Batch vs. Continuous – Western States: https://www.westernstates.com/batch-vs-continuous-centrifuge/

- Quadramatic – Western States | Centrifuge: https://www.westernstates.com/quadramatic/

- WSB-40 – Western States | Centrifuge: https://www.westernstates.com/wsb-40/

- Effective Solvent Recovery For Manufacturing Consumer Cannabis Products: https://yellowstoneextraction.com/2021/09/15/effective-solvent-recovery.html

- Chemical And Pharmaceutical Centrifuges – Western States: https://www.westernstates.com/chemical-and-pharmaceutical-centrifuges/

- Cannabis Solvent Recovery: What it is & How It Works? – Root Sciences: https://www.rootsciences.com/blog/what-is-solvent-recovery-and-how-does-it-work/

- Sugar Centrifuge Machines – Western States: https://www.westernstates.com/sugar-centrifuge-machines/

- Western States Basket Centrifuge Repair: https://centrifuge.com/western-states/

- Solvent Recovery and Recycling Market Size, Top Share and Forecast to 2033: https://straitsresearch.com/report/solvent-recovery-and-recycling-market

- Cannabis Extraction Equipment Market Size & Industry Analysis [2035]: https://www.marketgrowthreports.com/market-reports/cannabis-extraction-equipment-market-102676

- Solvent Recovery Systems Market Size & Share Report, 2034: https://www.gminsights.com/industry-analysis/solvent-recovery-systems-market

- Centrifuges – Western States – Western States | Centrifuge: https://www.westernstates.com/centrifuges/

- Cannabis Extraction Equipment Market Outlook, Opportunities, and Industry Growth 2025-2032 – SkyQuest Technology Consulting: https://www.skyquestt.com/report/cannabis-extraction-equipment-market