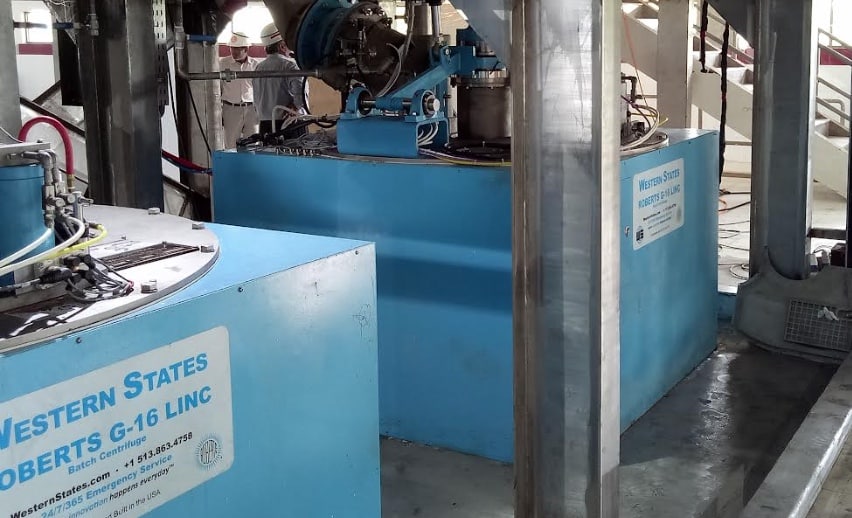

Efficiency should never come at the cost of a downgrade—the Roberts G-16 LINC Machine compounds on previous designs to bring a powerful new addition to factories everywhere. With new integrated display technology and a dedication to easy installation, the G-16 offers unique upgrades with familiar functionality to improve efficiency without the cost of complex factory changes.

What Changes to Expect in the G-16?

Specifications

Offered in four distinct models (900, 1100, 1400, and 1600), the G-16 offers increasing static and dynamic (pre-purge) volumes. Each model has a maximum cycle per hour of 28, with increasing hourly rates capping out at 44.2. The G-16 is also completely guarded to meet OSHA standards for factory worker safety. Our brochure outlines these technical specifications more complexly, so download a copy today!

Technology

We’ve integrated the Allen Bradley Panelview Plus 7 10.4” color LCD touchscreen display into our centrifuges design to provide cycle information, offer help screens, and track maintenance hour intervals. This integration also allows users to maintain alarm logs and track centrifuge performance information, increasing user efficiency while providing maintenance visibility. The G-16 also offers the Allen-Bradley Micrologix 1400 or CompactLogix PLC to further assist in diagnostic checks and troubleshooting.

Efficiency

The finalized design of the Roberts G-16 comes with several alterations to increase the machine’s overall efficiency. A precision paddle load control and downward opening spring valve increase the machine’s overall performance by increasing batch consistency and lowering potential obstructions. The G-16 offers a quickly completable maintenance checklist compared to its G-8 predecessor. Download our brochure for a complete look at the G-16’s technical maintenance checklist.

What if I already own a G-8 Centrifuge?

Our centrifuges are built to last, and we push hard for continual repair and uninterrupted service. Our “Repair & Upgrade” programs offer a unique opportunity to order service parts for older machines, upgrade current outfittings, or even fully refurbish older equipment.

To continue our goal of refurbishment and cost-effective upgrades, the Roberts G-16 LINC Batch Centrifuge fits within the structural steel of an existing G-8. This design lowers the costs of upgrading by negating the costs of structural steel redesigns and implementation. The G-16 utilizes a hung-motor system, much like the G-8, so that the motor of the LINC suspends above the curb. This positioning allows the G-16 to sit on the scaffolding exactly where the G-8 did. The design of this machine doesn’t replace all double-hung motors, but its new specifications, efficiency-based design, and its adapted technology saves your company money. These savings continue by allowing the newer machine to work with older steel structures.

Western States offers unique, customer-specific customization options upon request, providing each customer with a Western States machine access to our “Rebuilding & Upgrading” program. We plan never to phase out any of our centrifuges. Some Western States machines have been running for over 50 years. Please, contact us to discover how Western States can bring over 100 years of experience to your refinery.